The NVS-01 pump-vacuum system allows you to pump weakly fluid plastic masses, such as "shovel fuss", hydrofuse, a beer pellet with a concentration of more than 60%, solidol, cold glycerin, molasses and other plate lubricants, as well as other "difficult" liquids with All kinds of hard and soft inclusions up to 100 mm in size (depending on the diameter of the suction line). The maximum depth of self -consumption is 9 meters (depending on the viscosity of the liquid), the maximum pressure when heated is 7 bar. performance - up to 20 m3 per hour power consumption - up to 7.5 kW ..

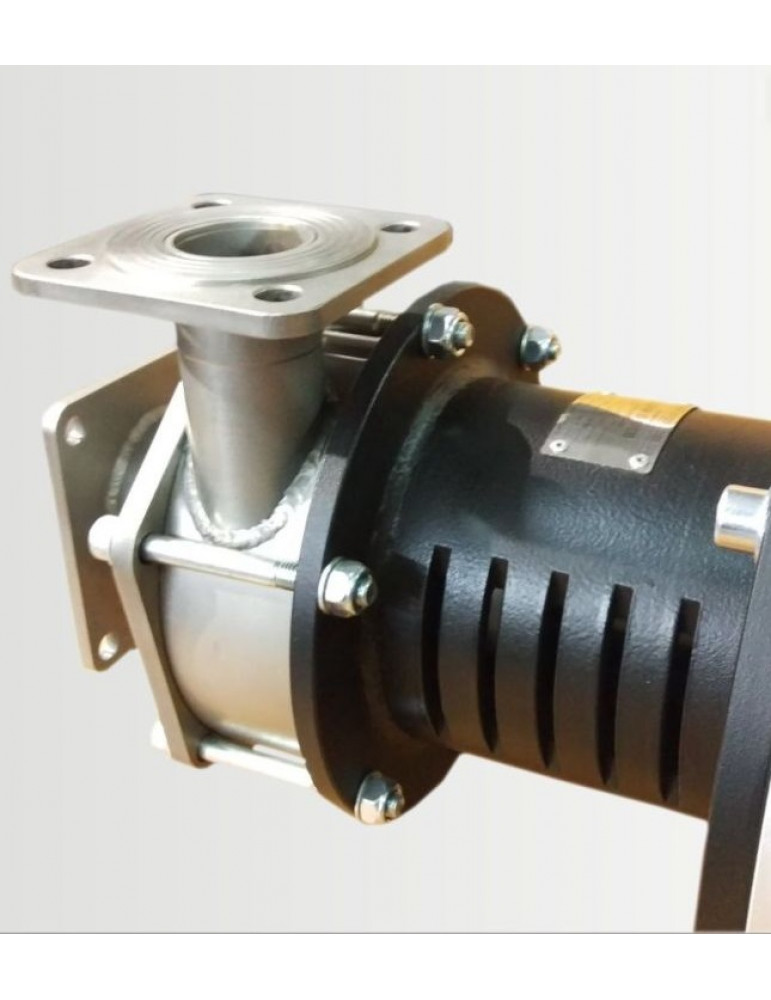

The installation consists of a working capacity, pressure and absorption pipes, as well as a vacuum-port compressor.

The principle of operation of the NVS-01 installation is somewhat similar to the operation of the assignor: the vacuum pump forms low pressure inside the working tank, under the influence of which the liquid is pumped inside through the receiving hose. In order to avoid overflowing the working capacity, a level sensor is installed inside it, with which the vacuum pump is automatically turned off. Next, blocking the groove valve, and switching the compressor into the discharge mode, the working fluid can be transported along the pressure pipeline due to the injection of excess pressure (up to 7 bar), for which it is necessary to open the pressure valve on the working capacity. With the devastation of the working capacity at the signal of the level sensor, the compressor automatically turns off. To pump the next portion of the fluid, the pressure valve is overlapped, excessive pressure is tired, the suction valve opens, the compressor switches into the absorption mode and turns on. The working capacity is equipped with a wide removable lid, which allows cleaning and washing easily.

The pumping rate depends on the volume of the working capacity, performance of the vacuum compressor and viscosity of the liquid.

Similar thick fluids are well pumped by screw pumps well, however, in the presence of all kinds of solid inclusions and other garbage, they quickly wear out, and the repair of a screw pair is very expensive, in addition, the cost of the screw pump itself is quite high.