The pumps are widely used in industry for pumping corrosive environments: chemical preparations, paints, lacquers, acids, solvents, petroleum products, etc.

Pump DS – 125 is bituminous and is used for pumping a variety of organic substances in the molten form. These include bitumen, tar, various modifications of mineral oils and tars.

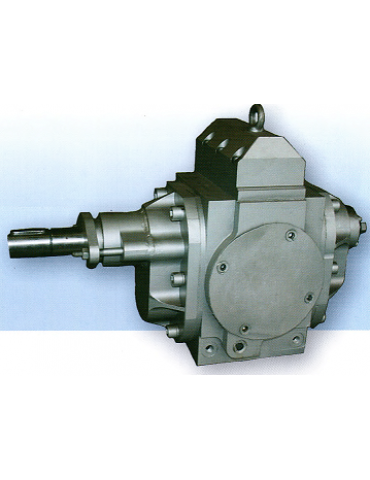

Asphalt pump brand DS – 125 has a cast iron housing, also made of it gear, which ensure reliable operation of the pump. The motor used for operation has a capacity, which ranges from 7.5 to 11 kW. And issued by the atmospheric pressure at the exit is 6 atmospheres.

Characteristics of bitumen pump DS -125:

• Pump type gear;

• Material – cast iron;

• Capacity – minimum 500 l/min;

• The rotation of shaft 450 rpm;

• Outlet pressure – 6 atmospheres;

• Operating temperature of the coolant – 100-180 0C;

• Size– 415*410*512 (mm);

• Total weight is 128 lbs.

Bitumen pump is used in asphalt mixing plants, bitumengravel units, baumkronenweg, wheelchairs, pavers, protosocial machines and road cutters.

Description bituminous ustanovki DM-134.

Bitumen pump DS-134 on the basis of pump DS-125 are designed for pumping viscous organic materials (various grades of bitumen, oils, tars, bitumen emulsions) with a viscosity of not more than 350 cSt at temperature +250°C. the unit is a welded frame design with mounted bitumen pump DS-125, an asynchronous motor with a squirrel cage rotor alternating current capacity of 7.5 or 11 kW (1500 rpm) industrial or explosion-proof, single-stage cylindrical reducer connected by coupling.

Pumps for bitumen ДС125 used in stationary installations (e.g. asphalt and concrete plants), and mobile point (e.g., DS-41). Bitumen is not explosive, but often explosion proof motor you need for technical conditions of the premises.

The correct pump is the key to a long and impeccable work of production.

Manufacturer of wooden pattern equipment of any complexity.