Condition

For example:

Pump A2 3V 63/25 B-TV1-R2-GE U2 TU 26-06-1546-89 < /Strong>

Pump A3 3V2 400/16 B-TD4-R4-GT-E 4 TU 26-06 -1546-89 , where:

">">>

-

-

-

-

-

K - chromonyle steel,

-

Yu -Alyumini,

-

A - old 09g2s,

-

without designation - st3, steel 20, cast iron;

TV - single end with auxiliary,

TD - double end,

TT - end -type tandem,

1 - JSC "HMS Livhydromash";

2 - LLC "needle Burgmann";

3 - CJSC NPO "Unihimtec";

4 - tram engineering;

5 - LLC "NKP" Hermetic "

6 - LLC "John Crane Rus"

7 - LLC "Aessil Rus"

8 - NKP "Megachkom"

P1 - 3826,

P2 - 1314,

P3 - SB -26,

P4 - others.

GE - electric heating,

GT - heating the coolant

without designation - without heating;

purpose

Three-screw 3B pump and electric pump units based on it are designed to pump non-aggressive liquids without abrasive impurities with lubricant, with kinematic viscosity from 0.1 × 10-4 to 7.5 × 10-4 m 2 <<< /span>/s (from 1.9 to 1000 В) and temperature up to 353 k (80 ° C).

The lower viscosity limit is limited to the lubricant of the pumped fluid. When pumping liquids similar to diesel fuel, the output pressure should be reduced to 0.5 MPa (5.0 kgf/cm 2 ). The upper viscosity limit is limited by the rotation frequency and the power of the component drive.

In agreement with the manufacturer, the use of pumps for pumping liquids with a temperature of up to 373 K (100 ° C) is allowed.

About the permissible pressure of the pump when pumping liquids that are excellent in physical and mechanical properties from oil products (oils, diesel fuel), it is necessary in each case to request the manufacturer.

The pump refers to general-purpose products (Ion) view 1 (restored) GOST 27.003-90. Climate execution U, category of placement during operation 3, as well as climatic execution T, category of placement during operation 2 according to GOST 15150-69.

Design

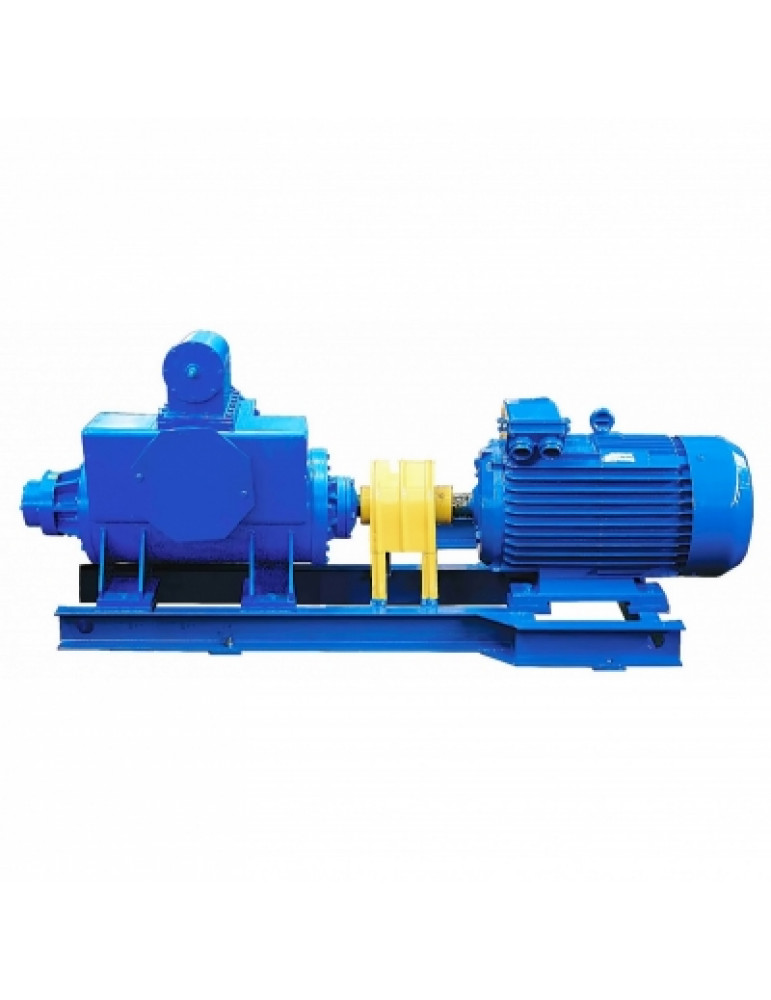

The electric pumping unit consists of a three -screw pump and an electric motor, which are subject to a common frame and connected by a coupling protected by a casing.

According to the principle of operation, the three -screw pump is voluminous. The pump consists of the following main details and assembly units: cases with lids, clips, one leading and two leders, end seal.

A clip is inserted inside the case with three adjacent cylindrical bores, in which there are one leading and two driven screws that serve to compact a leading screw.

The profile of the cutting of the screws is special, which provides their mutual conjugation, the cutting is two -mounting, on the leading screw - left, on the drivers - right.

When rotating the screws in the absorption chamber of the pump, discharge is created, as a result of which the pumped fluid under the pressure of the atmosphere enters the hollows of the screws, mutually closing during their rotation. The fluid volume closed in the cutting of the screws is moved straight into the clip without mixing and is supplanted into the discharge cavity. The direction of the entrance and exit of the pumped liquids in the drawings is indicated by arrows.

The type of shaft seal - end (single or double).

Application

">">>

-

-

-

Features/Advantages

-

Simplicity of the design, the possibility of repairing the replacement of worn parts

-

Uniform transportation of fluids without pulsation and mixing, as a result of which the use of pulsation or compensators in pipelines

is not required.

-

It is possible to manufacture the unit in both horizontal and vertical design

-

Pumps of type A3 3VX2 are equipped with single end seals, at the request of the customer can be equipped with double end seals

-

In pumps of type A3 3VX2, bearings are taken out of the pumped liquid, which significantly made it possible to increase the life of the pump, widespread when pumping fuel oil

-

good absorption of the pump up to 5 m or more, depending on the viscosity of the pumped liquid.

-

Stamps, characteristics of pumps 3B:

-

brands

feed, m³/h, no less

Pressure at the entrance to the pump, kgf/cm², no more than

Frequency of rotation, rpm

A1 3V 4/25B-TV1-r1-e2

6.8

2.5

2900

A1 3V 4/25-3/25B-TV1-5.5 U3

3

2.5

1450

A1 3V 4/25-3/25B-TV1-5.5.5 & y2

3

2.5

1450

A1 3V 4/25-3.2/4B-TV1-Р1-1.5th U2

3.2

2.5

2900

A1 3V 4/25-3.2/4B-TV1-R1-1.5 U3

3.2

2.5

2900

A1 3V 4/25-6.8/25B-TV1-7.5 U3

6.8

2.5

2900

A1 3V 4/25-6.8/25B-TV1-7.5th U2

6.8

2.5

2900

A1 3B 4/160

5.8

2900

A1 3V 4/160-4/100B

5.8

2900

A1 3V 8/40-11.5/40B-TV3-R1-30s

11.5

2.5

2900

A1 3V 10/35-11.5/40B-TV3-R1-30s

12

2.5

2900

A1 3V 12/25-17/25B-TV3-R1-22

17

2.5

2900

A1 3V 4/160-4/63b

5.8

2900

A1 3B 8/100

11.52

2900

A1 3V 8/25B

12.5

2.5

2900

A1 3V 8/25-11/10b

12.5

2.5

2900

A1 3V 8/100-11/100B-1

11.52

2900

A1 3B 16/25B-TV1-R1-e2

22

2900

A1 3V 16/25-10/25B-TV1-R1-15-U2

8

1450

A1 3V 16/25-10/25B-TV1-R1-15-U3

8

1450

A1 3V 16/25-11/6.3b-TV1-7.5-U2

10

2900

A1 3V 16/25-11/6.3b-TV1-7.5-U3

10

1450

A1 3V 16/25-24/6.3b-TV1-Р1-15 U2

24

2900

A1 3V 16/25-24/6.3b-TV1-Р1-15 U3

24

2900

A1 3V 16/25-24/6.3b-TV1-Р1-11 yu2

24

2900

A1 3V 16/25-22/25B-TV1-R1-22 U2

22

2900

A1 3B 16/

Pump A2 3V 63/25 B-TV1-R2-GE U2 TU 26-06-1546-89 < /Strong>

Pump A3 3V2 400/16 B-TD4-R4-GT-E 4 TU 26-06 -1546-89 , where:

- ">">>

- K - chromonyle steel,

- Yu -Alyumini,

- A - old 09g2s,

- without designation - st3, steel 20, cast iron;

purpose

Three-screw 3B pump and electric pump units based on it are designed to pump non-aggressive liquids without abrasive impurities with lubricant, with kinematic viscosity from 0.1 × 10-4 to 7.5 × 10-4 m 2 <<< /span>/s (from 1.9 to 1000 В) and temperature up to 353 k (80 ° C).

The lower viscosity limit is limited to the lubricant of the pumped fluid. When pumping liquids similar to diesel fuel, the output pressure should be reduced to 0.5 MPa (5.0 kgf/cm 2 ). The upper viscosity limit is limited by the rotation frequency and the power of the component drive.

In agreement with the manufacturer, the use of pumps for pumping liquids with a temperature of up to 373 K (100 ° C) is allowed.

About the permissible pressure of the pump when pumping liquids that are excellent in physical and mechanical properties from oil products (oils, diesel fuel), it is necessary in each case to request the manufacturer.

The pump refers to general-purpose products (Ion) view 1 (restored) GOST 27.003-90. Climate execution U, category of placement during operation 3, as well as climatic execution T, category of placement during operation 2 according to GOST 15150-69.

Design

The electric pumping unit consists of a three -screw pump and an electric motor, which are subject to a common frame and connected by a coupling protected by a casing.

According to the principle of operation, the three -screw pump is voluminous. The pump consists of the following main details and assembly units: cases with lids, clips, one leading and two leders, end seal.

A clip is inserted inside the case with three adjacent cylindrical bores, in which there are one leading and two driven screws that serve to compact a leading screw.

The profile of the cutting of the screws is special, which provides their mutual conjugation, the cutting is two -mounting, on the leading screw - left, on the drivers - right.

When rotating the screws in the absorption chamber of the pump, discharge is created, as a result of which the pumped fluid under the pressure of the atmosphere enters the hollows of the screws, mutually closing during their rotation. The fluid volume closed in the cutting of the screws is moved straight into the clip without mixing and is supplanted into the discharge cavity. The direction of the entrance and exit of the pumped liquids in the drawings is indicated by arrows.

The type of shaft seal - end (single or double).

Application

">">>

-

-

-

Features/Advantages

-

Simplicity of the design, the possibility of repairing the replacement of worn parts

-

Uniform transportation of fluids without pulsation and mixing, as a result of which the use of pulsation or compensators in pipelines

is not required.

-

It is possible to manufacture the unit in both horizontal and vertical design

-

Pumps of type A3 3VX2 are equipped with single end seals, at the request of the customer can be equipped with double end seals

-

In pumps of type A3 3VX2, bearings are taken out of the pumped liquid, which significantly made it possible to increase the life of the pump, widespread when pumping fuel oil

-

good absorption of the pump up to 5 m or more, depending on the viscosity of the pumped liquid.

-

Stamps, characteristics of pumps 3B:

-

brands

feed, m³/h, no less

Pressure at the entrance to the pump, kgf/cm², no more than

Frequency of rotation, rpm

A1 3V 4/25B-TV1-r1-e2

6.8

2.5

2900

A1 3V 4/25-3/25B-TV1-5.5 U3

3

2.5

1450

A1 3V 4/25-3/25B-TV1-5.5.5 & y2

3

2.5

1450

A1 3V 4/25-3.2/4B-TV1-Р1-1.5th U2

3.2

2.5

2900

A1 3V 4/25-3.2/4B-TV1-R1-1.5 U3

3.2

2.5

2900

A1 3V 4/25-6.8/25B-TV1-7.5 U3

6.8

2.5

2900

A1 3V 4/25-6.8/25B-TV1-7.5th U2

6.8

2.5

2900

A1 3B 4/160

5.8

2900

A1 3V 4/160-4/100B

5.8

2900

A1 3V 8/40-11.5/40B-TV3-R1-30s

11.5

2.5

2900

A1 3V 10/35-11.5/40B-TV3-R1-30s

12

2.5

2900

A1 3V 12/25-17/25B-TV3-R1-22

17

2.5

2900

A1 3V 4/160-4/63b

5.8

2900

A1 3B 8/100

11.52

2900

A1 3V 8/25B

12.5

2.5

2900

A1 3V 8/25-11/10b

12.5

2.5

2900

A1 3V 8/100-11/100B-1

11.52

2900

A1 3B 16/25B-TV1-R1-e2

22

2900

A1 3V 16/25-10/25B-TV1-R1-15-U2

8

1450

A1 3V 16/25-10/25B-TV1-R1-15-U3

8

1450

A1 3V 16/25-11/6.3b-TV1-7.5-U2

10

2900

A1 3V 16/25-11/6.3b-TV1-7.5-U3

10

1450

A1 3V 16/25-24/6.3b-TV1-Р1-15 U2

24

2900

A1 3V 16/25-24/6.3b-TV1-Р1-15 U3

24

2900

A1 3V 16/25-24/6.3b-TV1-Р1-11 yu2

24

2900

A1 3V 16/25-22/25B-TV1-R1-22 U2

22

2900

A1 3B 16/

The electric pumping unit consists of a three -screw pump and an electric motor, which are subject to a common frame and connected by a coupling protected by a casing.

According to the principle of operation, the three -screw pump is voluminous. The pump consists of the following main details and assembly units: cases with lids, clips, one leading and two leders, end seal.

A clip is inserted inside the case with three adjacent cylindrical bores, in which there are one leading and two driven screws that serve to compact a leading screw.

The profile of the cutting of the screws is special, which provides their mutual conjugation, the cutting is two -mounting, on the leading screw - left, on the drivers - right.

When rotating the screws in the absorption chamber of the pump, discharge is created, as a result of which the pumped fluid under the pressure of the atmosphere enters the hollows of the screws, mutually closing during their rotation. The fluid volume closed in the cutting of the screws is moved straight into the clip without mixing and is supplanted into the discharge cavity. The direction of the entrance and exit of the pumped liquids in the drawings is indicated by arrows.

The type of shaft seal - end (single or double).

Application

">">>

-

-

-

Features/Advantages

-

Simplicity of the design, the possibility of repairing the replacement of worn parts

-

Uniform transportation of fluids without pulsation and mixing, as a result of which the use of pulsation or compensators in pipelines

is not required.

-

It is possible to manufacture the unit in both horizontal and vertical design

-

Pumps of type A3 3VX2 are equipped with single end seals, at the request of the customer can be equipped with double end seals

-

In pumps of type A3 3VX2, bearings are taken out of the pumped liquid, which significantly made it possible to increase the life of the pump, widespread when pumping fuel oil

-

good absorption of the pump up to 5 m or more, depending on the viscosity of the pumped liquid.

-

Stamps, characteristics of pumps 3B:

-

brands

feed, m³/h, no less

Pressure at the entrance to the pump, kgf/cm², no more than

Frequency of rotation, rpm

A1 3V 4/25B-TV1-r1-e2

6.8

2.5

2900

A1 3V 4/25-3/25B-TV1-5.5 U3

3

2.5

1450

A1 3V 4/25-3/25B-TV1-5.5.5 & y2

3

2.5

1450

A1 3V 4/25-3.2/4B-TV1-Р1-1.5th U2

3.2

2.5

2900

A1 3V 4/25-3.2/4B-TV1-R1-1.5 U3

3.2

2.5

2900

A1 3V 4/25-6.8/25B-TV1-7.5 U3

6.8

2.5

2900

A1 3V 4/25-6.8/25B-TV1-7.5th U2

6.8

2.5

2900

A1 3B 4/160

5.8

2900

A1 3V 4/160-4/100B

5.8

2900

A1 3V 8/40-11.5/40B-TV3-R1-30s

11.5

2.5

2900

A1 3V 10/35-11.5/40B-TV3-R1-30s

12

2.5

2900

A1 3V 12/25-17/25B-TV3-R1-22

17

2.5

2900

A1 3V 4/160-4/63b

5.8

2900

A1 3B 8/100

11.52

2900

A1 3V 8/25B

12.5

2.5

2900

A1 3V 8/25-11/10b

12.5

2.5

2900

A1 3V 8/100-11/100B-1

11.52

2900

A1 3B 16/25B-TV1-R1-e2

22

2900

A1 3V 16/25-10/25B-TV1-R1-15-U2

8

1450

A1 3V 16/25-10/25B-TV1-R1-15-U3

8

1450

A1 3V 16/25-11/6.3b-TV1-7.5-U2

10

2900

A1 3V 16/25-11/6.3b-TV1-7.5-U3

10

1450

A1 3V 16/25-24/6.3b-TV1-Р1-15 U2

24

2900

A1 3V 16/25-24/6.3b-TV1-Р1-15 U3

24

2900

A1 3V 16/25-24/6.3b-TV1-Р1-11 yu2

24

2900

A1 3V 16/25-22/25B-TV1-R1-22 U2

22

2900

A1 3B 16/

- ">">>

-

Features/Advantages

- Simplicity of the design, the possibility of repairing the replacement of worn parts

- Uniform transportation of fluids without pulsation and mixing, as a result of which the use of pulsation or compensators in pipelines is not required.

- It is possible to manufacture the unit in both horizontal and vertical design

- Pumps of type A3 3VX2 are equipped with single end seals, at the request of the customer can be equipped with double end seals

- In pumps of type A3 3VX2, bearings are taken out of the pumped liquid, which significantly made it possible to increase the life of the pump, widespread when pumping fuel oil

- good absorption of the pump up to 5 m or more, depending on the viscosity of the pumped liquid.

-

Stamps, characteristics of pumps 3B:

-

brands

feed, m³/h, no less

Pressure at the entrance to the pump, kgf/cm², no more than

Frequency of rotation, rpm

A1 3V 4/25B-TV1-r1-e2

6.8

2.5

2900

A1 3V 4/25-3/25B-TV1-5.5 U3

3

2.5

1450

A1 3V 4/25-3/25B-TV1-5.5.5 & y2

3

2.5

1450

A1 3V 4/25-3.2/4B-TV1-Р1-1.5th U2

3.2

2.5

2900

A1 3V 4/25-3.2/4B-TV1-R1-1.5 U3

3.2

2.5

2900

A1 3V 4/25-6.8/25B-TV1-7.5 U3

6.8

2.5

2900

A1 3V 4/25-6.8/25B-TV1-7.5th U2

6.8

2.5

2900

A1 3B 4/160

5.8

2900

A1 3V 4/160-4/100B

5.8

2900

A1 3V 8/40-11.5/40B-TV3-R1-30s

11.5

2.5

2900

A1 3V 10/35-11.5/40B-TV3-R1-30s

12

2.5

2900

A1 3V 12/25-17/25B-TV3-R1-22

17

2.5

2900

A1 3V 4/160-4/63b

5.8

2900

A1 3B 8/100

11.52

2900

A1 3V 8/25B

12.5

2.5

2900

A1 3V 8/25-11/10b

12.5

2.5

2900

A1 3V 8/100-11/100B-1

11.52

2900

A1 3B 16/25B-TV1-R1-e2

22

2900

A1 3V 16/25-10/25B-TV1-R1-15-U2

8

1450

A1 3V 16/25-10/25B-TV1-R1-15-U3

8

1450

A1 3V 16/25-11/6.3b-TV1-7.5-U2

10

2900

A1 3V 16/25-11/6.3b-TV1-7.5-U3

10

1450

A1 3V 16/25-24/6.3b-TV1-Р1-15 U2

24

2900

A1 3V 16/25-24/6.3b-TV1-Р1-15 U3

24

2900

A1 3V 16/25-24/6.3b-TV1-Р1-11 yu2

24

2900

A1 3V 16/25-22/25B-TV1-R1-22 U2

22

2900

A1 3B 16/