Condition

AS-Hax1/16-K-TD-U3.1 TU 3631-326-0021795-2009 , where:

">">>

- As -execution for nuclear stations;

- VKS - type of pump: VK - vortex console, VKS - vortex console -style;

- 1 -feed, l/s;

- 16 -pressure, m;

- K -Material of the details of the prototype part: K-of stainless steel;

- TD -type of shaft seal: T -Odinar end, TD -double end;

- U3.1 -climatic execution and category of accommodation according to GOST15150-69.

Appointment

Electric power pumps of the AS-VK type (further units) are designed to pump neutral, weakly aggressive, harmful and explosive liquids with kinematic viscosity up to 36 · 10-6 m 2 /s (36 SST), With the content of solid inclusions, not more than 0.01% in weight and size of not more than 0.05 mm, in which the materials of the prototype part do not allow the linear speed of continuous corrosion of more than 0.1 mm/year according to GOST 9.908-85.

For the supply of nuclear energy facilities, the pumping units of the AS-VK and AS-VKS are developed in accordance with the supply agreement and the technical requirements of the customer. When ordering the unit, it is necessary to indicate:

- conditioning of the unit;

- the system in which the unit will work;

-Security class and safety element for PN AE G-01-011-97;

-a group of equipment for the PN AE G-7-008-89 (if necessary);

-category of seismic resistance in NP-031-01.

The pumps included in the units are reliable for the products of a specific purpose (ICN), the type of product I (restored) GOST 27.003.

Design

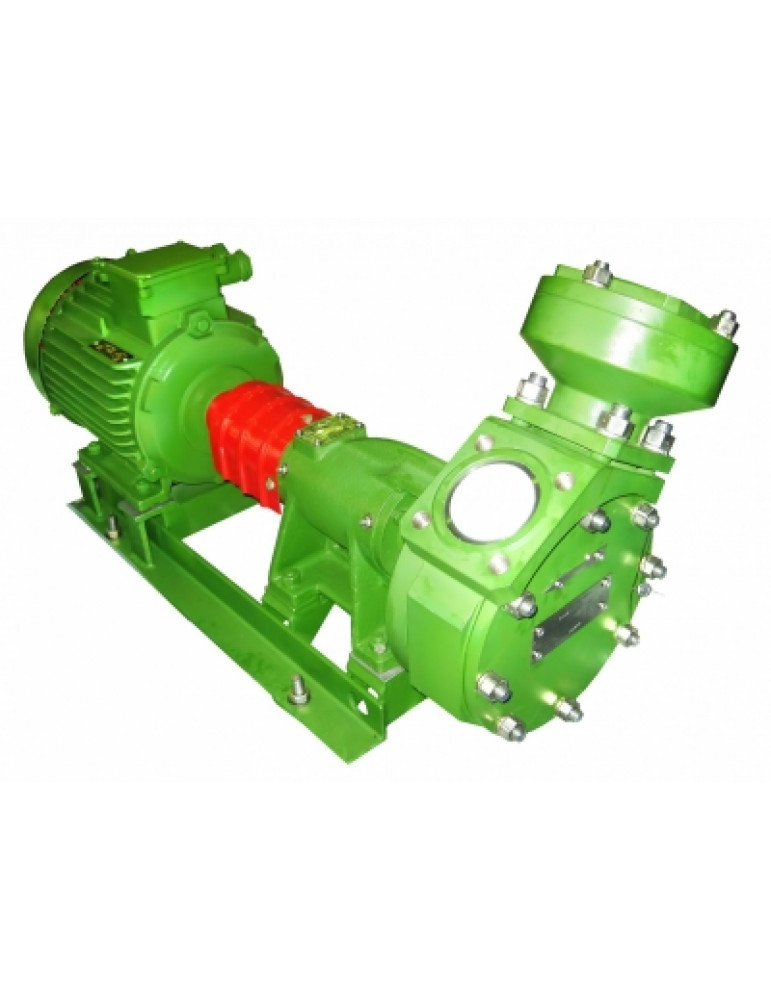

The unit consists of a pump and a drive electric motor installed on a common foundation frame and interconnected using an elastic coupling. A protective casing is installed above the coupling.

Pump - vortex, single -stage, horizontal, console.

Moving the liquid medium through the ring channel and giving it the necessary energy is carried out by a working wheel, which is a disk with radially located blades.

The working chamber of the running part of the pump is made in the case, the cover of the housing and the spacer and is a ring channel reporting to the entrance and output pump pipe. The absorption and guide parts of the channel are divided by a jumper (delay).

The working wheel, mounted on the shaft of the venarable, has the possibility of free movement in the axial direction. The holes available in the disk allow you to unload the working wheel from the axial forces.

The pump shaft rotates in two ball -bearing supports installed in the pump bracket.

The direction of rotation of the shaft for the pump is indifferent, determined only by the position of pipelines and the prerequisite for moving the fluid from the absorbing to the pressure pipeline along the large arc.

The pump shaft is compacted by a double or single end seal.

Application

">">>

-

Features/advantages

-

A wide pressure range at low feeds

-

Linear dependence of the pressure on the feed

-

Good self -supporting ability

-

Designed for use at nuclear power plants

AS-Hax1/16-K-TD-U3.1 TU 3631-326-0021795-2009 , where:

- ">">>

- As -execution for nuclear stations;

- VKS - type of pump: VK - vortex console, VKS - vortex console -style;

- 1 -feed, l/s;

- 16 -pressure, m;

- K -Material of the details of the prototype part: K-of stainless steel;

- TD -type of shaft seal: T -Odinar end, TD -double end;

- U3.1 -climatic execution and category of accommodation according to GOST15150-69.

Appointment

Electric power pumps of the AS-VK type (further units) are designed to pump neutral, weakly aggressive, harmful and explosive liquids with kinematic viscosity up to 36 · 10-6 m 2 /s (36 SST), With the content of solid inclusions, not more than 0.01% in weight and size of not more than 0.05 mm, in which the materials of the prototype part do not allow the linear speed of continuous corrosion of more than 0.1 mm/year according to GOST 9.908-85.

For the supply of nuclear energy facilities, the pumping units of the AS-VK and AS-VKS are developed in accordance with the supply agreement and the technical requirements of the customer. When ordering the unit, it is necessary to indicate:

- conditioning of the unit;

- the system in which the unit will work;

-Security class and safety element for PN AE G-01-011-97;

-a group of equipment for the PN AE G-7-008-89 (if necessary);

-category of seismic resistance in NP-031-01.

The pumps included in the units are reliable for the products of a specific purpose (ICN), the type of product I (restored) GOST 27.003.

Design

The unit consists of a pump and a drive electric motor installed on a common foundation frame and interconnected using an elastic coupling. A protective casing is installed above the coupling.

Pump - vortex, single -stage, horizontal, console.

Moving the liquid medium through the ring channel and giving it the necessary energy is carried out by a working wheel, which is a disk with radially located blades.

The working chamber of the running part of the pump is made in the case, the cover of the housing and the spacer and is a ring channel reporting to the entrance and output pump pipe. The absorption and guide parts of the channel are divided by a jumper (delay).

The working wheel, mounted on the shaft of the venarable, has the possibility of free movement in the axial direction. The holes available in the disk allow you to unload the working wheel from the axial forces.

The pump shaft rotates in two ball -bearing supports installed in the pump bracket.

The direction of rotation of the shaft for the pump is indifferent, determined only by the position of pipelines and the prerequisite for moving the fluid from the absorbing to the pressure pipeline along the large arc.

The pump shaft is compacted by a double or single end seal.

Application

">">>

-

Features/advantages

-

A wide pressure range at low feeds

-

Linear dependence of the pressure on the feed

-

Good self -supporting ability

-

Designed for use at nuclear power plants

Electric power pumps of the AS-VK type (further units) are designed to pump neutral, weakly aggressive, harmful and explosive liquids with kinematic viscosity up to 36 · 10-6 m 2 /s (36 SST), With the content of solid inclusions, not more than 0.01% in weight and size of not more than 0.05 mm, in which the materials of the prototype part do not allow the linear speed of continuous corrosion of more than 0.1 mm/year according to GOST 9.908-85.

For the supply of nuclear energy facilities, the pumping units of the AS-VK and AS-VKS are developed in accordance with the supply agreement and the technical requirements of the customer. When ordering the unit, it is necessary to indicate:

- conditioning of the unit;

- the system in which the unit will work;

-Security class and safety element for PN AE G-01-011-97;

-a group of equipment for the PN AE G-7-008-89 (if necessary);

-category of seismic resistance in NP-031-01.

The pumps included in the units are reliable for the products of a specific purpose (ICN), the type of product I (restored) GOST 27.003.

The unit consists of a pump and a drive electric motor installed on a common foundation frame and interconnected using an elastic coupling. A protective casing is installed above the coupling.

Pump - vortex, single -stage, horizontal, console.

Moving the liquid medium through the ring channel and giving it the necessary energy is carried out by a working wheel, which is a disk with radially located blades.

The working chamber of the running part of the pump is made in the case, the cover of the housing and the spacer and is a ring channel reporting to the entrance and output pump pipe. The absorption and guide parts of the channel are divided by a jumper (delay).

The working wheel, mounted on the shaft of the venarable, has the possibility of free movement in the axial direction. The holes available in the disk allow you to unload the working wheel from the axial forces.

The pump shaft rotates in two ball -bearing supports installed in the pump bracket.

The direction of rotation of the shaft for the pump is indifferent, determined only by the position of pipelines and the prerequisite for moving the fluid from the absorbing to the pressure pipeline along the large arc.

The pump shaft is compacted by a double or single end seal.

Application

">">>

-

Features/advantages

-

A wide pressure range at low feeds

-

Linear dependence of the pressure on the feed

-

Good self -supporting ability

-

Designed for use at nuclear power plants

- ">">>

- A wide pressure range at low feeds

- Linear dependence of the pressure on the feed

- Good self -supporting ability

- Designed for use at nuclear power plants

Features/advantages