Condition

For example: DV 200-660-A-b-b-С/C-–-uhl 3.1 TU3631- 426-00217975-2014 , where:

">">>

- D - Delium- a series of pumps

- V - Val location: V- vertical, without designation- horizontal

- 200 -nominal diameter of the output pipe, mm

- 660 -conditional diameter of the working wheel, mm

- A -the execution of the rotor

- B - Wheel cutting: without designation- the main wheel, A, B- the working wheel turning index

- s/s -execution of the case/Wheel Wheel:

Without designation-gray cast iron / gray cast iron

Sh / h-spherical cast iron / gray cast iron

C / s-steel / steel

B / B-Gray cast iron / bronze

N / B-stainless steel / bronze

N / n-stainless steel / stainless steel

D/d - steel duplex/steel duplex

- t -shaft compaction:

Without purpose-an elaboration

T is the end of the single

TS-end with auxiliary

TT - Double end (at the request of the customer)

- e - the performance of the pump (unit) intended for explosive and fire hazardous production

- UHL 3.1 -climatic execution and category of accommodation (U2, T2)

)

Appointment

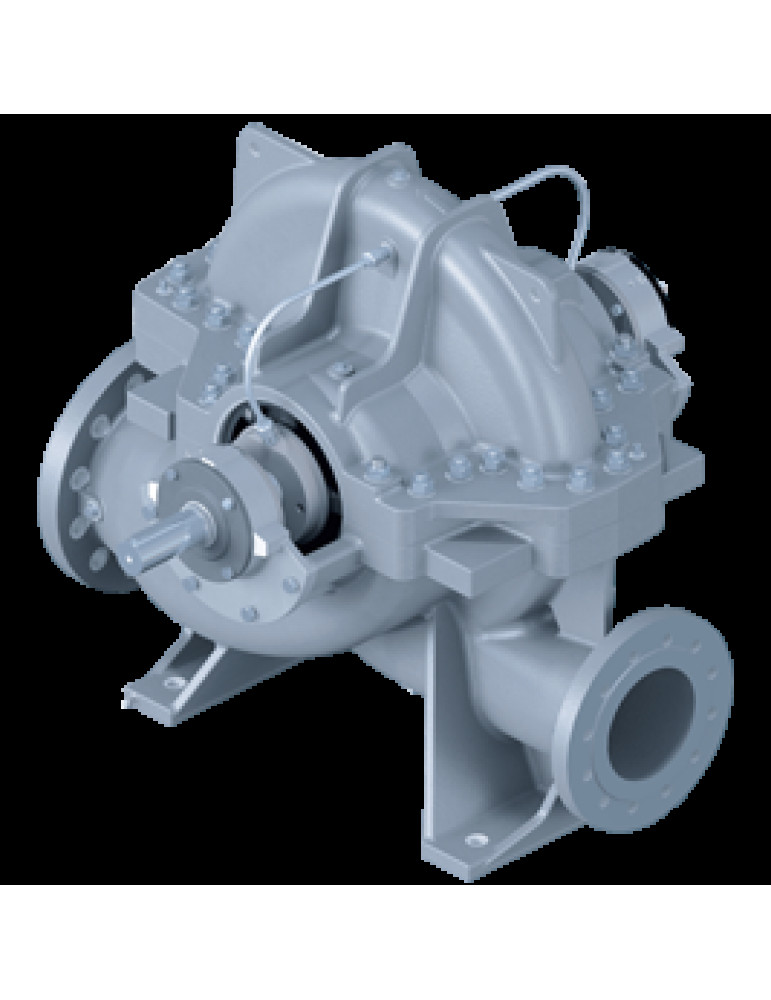

Series Delium-pumps of a new generation with a bilateral entrance and with a horizontal connector of the case. Delium pumps are created taking into account modern requirements for energy consumption, reliability and long service life. Pump hydraulics are designed using modern computer modeling methods.

A wide range of delumes (& gt; 45) and the use of at least two interchangeable workers The wheels for one body size allows you to choose a pump for any tasks within the feed range from 80 to 10,000 m3/h and the pressure of 5 to 200 m. Work wheels are made in accordance with the requirements of the customer. A high degree of unification of the main parts for various models of pumps significantly reduces the cost of maintenance.

Vertical installation of Delium pumps , as a standard option, is used in technical rooms where horizontal installation is impossible. The vertical installation of the pump also provides engine protection in case of flooding of the machine department.

The characteristics of Delium pumps allow them to operate at Parallel installation and regulate parameters using frequency transducer drives. Pumps can be operated in any climatic conditions with a temperature range from -60 ° C to + 60 ° C .

Stamps (46) , characteristics of Delium pumps (Delium):

Brands

Feed (nomin.), M³/h

Ples, m

Permissible pressure at the input for gray cast iron, kgf/s2

Permissible pressure at the input for steel and ball-visible cast iron, kgf/s2

Power consumed by the pump (max.), KW

Rotation frequency, rpm

Rotation frequency, C˜¹

PPD pump, %

Permissible cavitation reserve, m, no more

D 125-250a

288

16

13.5

22.5

17

1450

24.2

86

1.6

D 125-250b

257

15

13.5

22.5

14

1450

24.2

84

1.7

D 125-320A

316

29

12

22.5

35

1450

24.2

83

1.8

D 125-320b

280

28

12

22.5

29.5

1450

24.2

83

1.6

D 125-400a

315

52

10.5

22.5

63

1450

24.2

82

1.9

D 125-400b

325

52

10.5

22.5

65

1450

24.2

81

1.9

D 125-480a

324

80

7.4

22.5

85

1450

24.2

81

1.7

D 125-480b

297

74

7.4

22.5

82

1450

24.2

79

1.6

D 150-290a

452

21

13.2

22.5

36

1450

24.2

85

1.8

For example: DV 200-660-A-b-b-С/C-–-uhl 3.1 TU3631- 426-00217975-2014 , where:

- ">">>

- D - Delium- a series of pumps

- V - Val location: V- vertical, without designation- horizontal

- 200 -nominal diameter of the output pipe, mm

- 660 -conditional diameter of the working wheel, mm

- A -the execution of the rotor

- B - Wheel cutting: without designation- the main wheel, A, B- the working wheel turning index

- s/s -execution of the case/Wheel Wheel:

Without designation-gray cast iron / gray cast iron

Sh / h-spherical cast iron / gray cast iron

C / s-steel / steel

B / B-Gray cast iron / bronze

N / B-stainless steel / bronze

N / n-stainless steel / stainless steel

D/d - steel duplex/steel duplex - t -shaft compaction:

Without purpose-an elaboration

T is the end of the single

TS-end with auxiliary

TT - Double end (at the request of the customer) - e - the performance of the pump (unit) intended for explosive and fire hazardous production

- UHL 3.1 -climatic execution and category of accommodation (U2, T2) )

Appointment

Series Delium-pumps of a new generation with a bilateral entrance and with a horizontal connector of the case. Delium pumps are created taking into account modern requirements for energy consumption, reliability and long service life. Pump hydraulics are designed using modern computer modeling methods.

A wide range of delumes (& gt; 45) and the use of at least two interchangeable workers The wheels for one body size allows you to choose a pump for any tasks within the feed range from 80 to 10,000 m3/h and the pressure of 5 to 200 m. Work wheels are made in accordance with the requirements of the customer. A high degree of unification of the main parts for various models of pumps significantly reduces the cost of maintenance.

Vertical installation of Delium pumps , as a standard option, is used in technical rooms where horizontal installation is impossible. The vertical installation of the pump also provides engine protection in case of flooding of the machine department.

The characteristics of Delium pumps allow them to operate at Parallel installation and regulate parameters using frequency transducer drives. Pumps can be operated in any climatic conditions with a temperature range from -60 ° C to + 60 ° C .

Stamps (46) , characteristics of Delium pumps (Delium):

Brands

Feed (nomin.), M³/h

Ples, m

Permissible pressure at the input for gray cast iron, kgf/s2

Permissible pressure at the input for steel and ball-visible cast iron, kgf/s2

Power consumed by the pump (max.), KW

Rotation frequency, rpm

Rotation frequency, C˜¹

PPD pump, %

Permissible cavitation reserve, m, no more

D 125-250a

288

16

13.5

22.5

17

1450

24.2

86

1.6

D 125-250b

257

15

13.5

22.5

14

1450

24.2

84

1.7

D 125-320A

316

29

12

22.5

35

1450

24.2

83

1.8

D 125-320b

280

28

12

22.5

29.5

1450

24.2

83

1.6

D 125-400a

315

52

10.5

22.5

63

1450

24.2

82

1.9

D 125-400b

325

52

10.5

22.5

65

1450

24.2

81

1.9

D 125-480a

324

80

7.4

22.5

85

1450

24.2

81

1.7

D 125-480b

297

74

7.4

22.5

82

1450

24.2

79

1.6

D 150-290a

452

21

13.2

22.5

36

1450

24.2

85

1.8

Series Delium-pumps of a new generation with a bilateral entrance and with a horizontal connector of the case. Delium pumps are created taking into account modern requirements for energy consumption, reliability and long service life. Pump hydraulics are designed using modern computer modeling methods.

A wide range of delumes (& gt; 45) and the use of at least two interchangeable workers The wheels for one body size allows you to choose a pump for any tasks within the feed range from 80 to 10,000 m3/h and the pressure of 5 to 200 m. Work wheels are made in accordance with the requirements of the customer. A high degree of unification of the main parts for various models of pumps significantly reduces the cost of maintenance.

Vertical installation of Delium pumps , as a standard option, is used in technical rooms where horizontal installation is impossible. The vertical installation of the pump also provides engine protection in case of flooding of the machine department.

The characteristics of Delium pumps allow them to operate at Parallel installation and regulate parameters using frequency transducer drives. Pumps can be operated in any climatic conditions with a temperature range from -60 ° C to + 60 ° C .

Stamps (46) , characteristics of Delium pumps (Delium):

Brands

Feed (nomin.), M³/h

Ples, m

Permissible pressure at the input for gray cast iron, kgf/s2

Permissible pressure at the input for steel and ball-visible cast iron, kgf/s2

Power consumed by the pump (max.), KW

Rotation frequency, rpm

Rotation frequency, C˜¹

PPD pump, %

Permissible cavitation reserve, m, no more

D 125-250a

288

16

13.5

22.5

17

1450

24.2

86

1.6

D 125-250b

257

15

13.5

22.5

14

1450

24.2

84

1.7

D 125-320A

316

29

12

22.5

35

1450

24.2

83

1.8

D 125-320b

280

28

12

22.5

29.5

1450

24.2

83

1.6

D 125-400a

315

52

10.5

22.5

63

1450

24.2

82

1.9

D 125-400b

325

52

10.5

22.5

65

1450

24.2

81

1.9

D 125-480a

324

80

7.4

22.5

85

1450

24.2

81

1.7

D 125-480b

297

74

7.4

22.5

82

1450

24.2

79

1.6

D 150-290a

452

21

13.2

22.5

36

1450

24.2

85

1.8

| Brands | Feed (nomin.), M³/h | Ples, m | Permissible pressure at the input for gray cast iron, kgf/s2 | Permissible pressure at the input for steel and ball-visible cast iron, kgf/s2 | Power consumed by the pump (max.), KW | Rotation frequency, rpm | Rotation frequency, C˜¹ | PPD pump, % | Permissible cavitation reserve, m, no more |

|

D 125-250a

|

288 | 16 | 13.5 | 22.5 | 17 | 1450 | 24.2 | 86 | 1.6 |

|

D 125-250b

|

257 | 15 | 13.5 | 22.5 | 14 | 1450 | 24.2 | 84 | 1.7 |

|

D 125-320A

|

316 | 29 | 12 | 22.5 | 35 | 1450 | 24.2 | 83 | 1.8 |

|

D 125-320b

|

280 | 28 | 12 | 22.5 | 29.5 | 1450 | 24.2 | 83 | 1.6 |

|

D 125-400a

|

315 | 52 | 10.5 | 22.5 | 63 | 1450 | 24.2 | 82 | 1.9 |

|

D 125-400b

|

325 | 52 | 10.5 | 22.5 | 65 | 1450 | 24.2 | 81 | 1.9 |

|

D 125-480a

|

324 | 80 | 7.4 | 22.5 | 85 | 1450 | 24.2 | 81 | 1.7 |

|

D 125-480b

|

297 | 74 | 7.4 | 22.5 | 82 | 1450 | 24.2 | 79 | 1.6 |

|

D 150-290a

|

452 | 21 | 13.2 | 22.5 | 36 | 1450 | 24.2 | 85 | 1.8 |

|

|