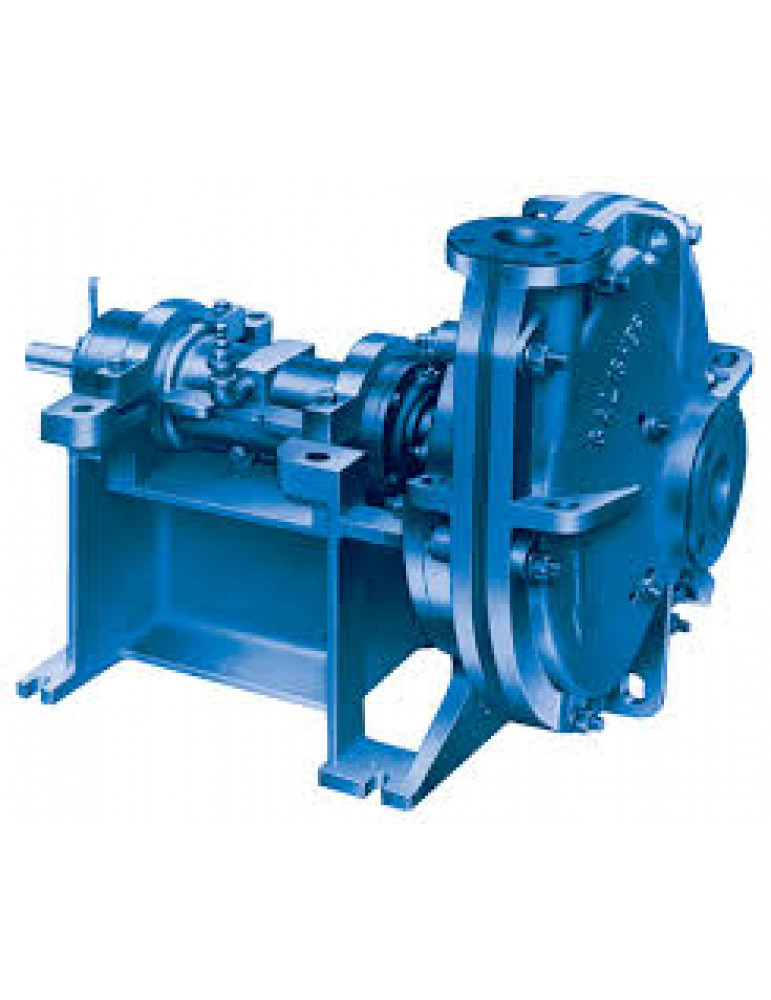

Warman slide pumps are used for hydraulic transportation of highly abrasive materials in the most difficult operating conditions.

Warman slide pumps are designed according to a special technical assignment of the customer and, therefore, the most fully and optimally meet his needs.

The design of the Warman slide pump has gained experience in many industrial operations and many improvements and many improvements and many improvements Therefore, the Warman sliding pump is a pump with the most minimum operational cost.

Warman slide pumps have the widest selection of wear-resistant materials from which are made of the prototing parts. The selection of the optimal material of the Warman sliding pump, depending on the operating conditions, gives maximum efficiency and the smallest costs.

Advantages of the Slame pump Warman:

- the possibility of choosing several wear-resistant parts of the prototal part of the prototypery part of the process pump Warman; < /span>

- the most effective design of the coching and working wheel of the slot pump Warman;

- Frequency and power are selected for specific operating conditions of the Warman slim pump; Span>

- maximum size and content of solid particles in the pumped environment;

- the minimum volume of repairs and downtime Warman; P>

- Reduced operating costs for the USHman slide pump;

-simplicity of installation and maintenance of the Schlama pump Warman.

Technical characteristics of the Warman pumps series AHR

Survery of the pump

Maximum drive power, kW

Feed, cubic meter/hour

Ples, m

Rotation frequency, rpm

Maximum efficiency, %

NPSH, M

The diameter of the working wheel, mm

2/1.5V-An

15

32.5 - 72

6 - 58

1200 - 3200

45

3.5 - 8

184

3/2-an

30

39.6 - 86.4

12 - 64

1300 - 2700

55

4 - 6

214

4/3-o

30

86.4 - 198

9 - 52

1000 - 2200

71

4 - 6

245

4/3D-An

60

86.4 - 198

9 - 52

1000 - 2200

71

4 - 6

245

6/4D-An

60

162 - 360

12 - 56

800 - 1550

65

5 - 8

365

6/4-an

120

162 - 360

12 - 56

800 - 1550

65

5 - 8

365

8/6-an

120

360 - 828

10 - 61

500 - 1140

72

2 - 9

510

8/6F-An

300

360 - 828

10 - 61

500 - 1140

72

2 - 9

510

10/8f-an

260

612 - 1368

11 - 61

400 - 850

71

4 - 10

686

10/8st-An

560

612 - 1368

11 - 61

400 - 850

71

4 - 10

686

12/10st-an

560

936 - 1980

7 - 68

300 - 800

82

6

762

Survery of the pump

Maximum drive power, kW

Feed, cubic meter/hour