Description

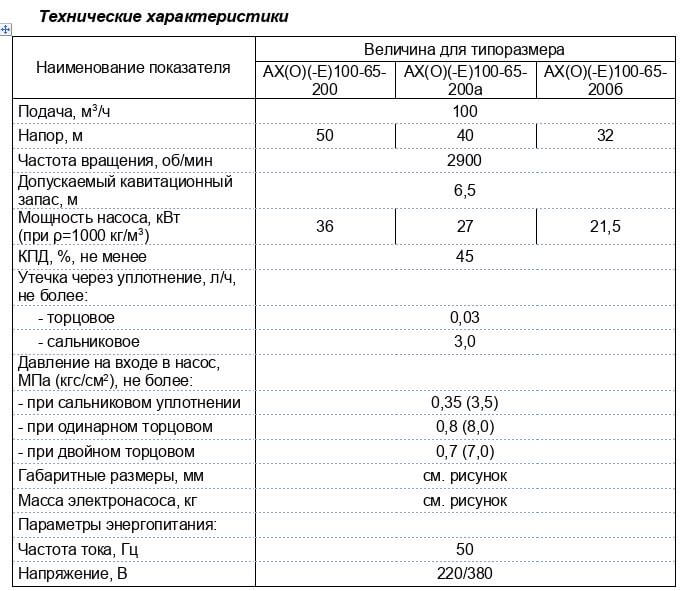

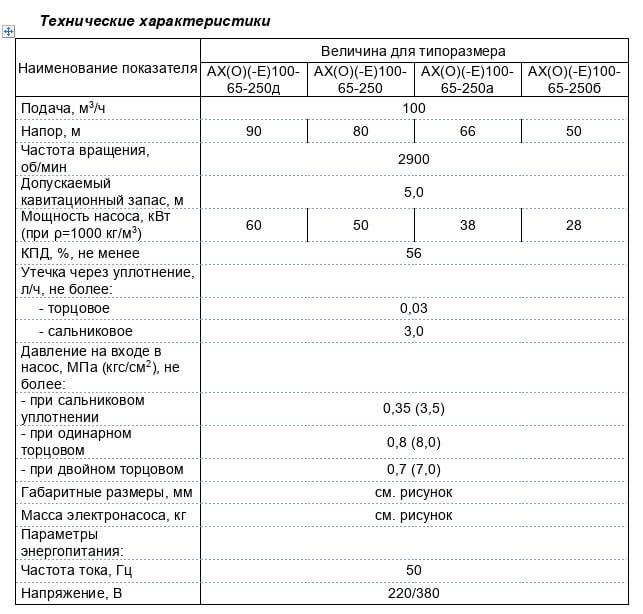

Units of Electroly pumping stamps Ah (O) (-E) 100-65-200 (subsequently units) are designed to pump pure neutral fluids with kinematic viscosity up to 30*10-6 m²/s, having solid inclusions of not more than 1.0 mm, voluminous volumetric The concentration of which is not more than 1.5 %, a density of not more: 1850 kg/m³, with the temperature of the pumped liquid from minus 40 to + 90 ºС, from minus 40 to + 120 ºС for executions K, E, and, and from 0 up to + 250 ºС for the execution of aho (s).

The body of the design of the design of the AHO (-e) has a camera into which the coolant is supplied at all.

At the request of the customer, the pumps performed by AHO (s) can be delivered with a heating chamber on the pump body from the absorption.

Units of general industrial performance do not allow the installation and operation of them in explosive and fire hazardous industries and should not be used to pump combustible and easily igniting liquids.

Ax (o) units can be made in constructive performance E for explosive fire hazardous zones and 2 classes of premises and external attitudes and external installations According to TR TS 012/2011; GOST 31438.1; GOST 12.1.011 and other regulatory documents, in which pairs, gases and fogs of pumped liquids form explosion-hazardous mixtures of categories IIa with air; IIB and groups T1, T2, T3, T4 depending on the temperature of the mixture ignition, with the exception of liquids with oxygen dissolved in them, detonating molten metals, liquefied gases, radioactive liquids and other similar media.

Environmental conditions:

- temperature from minus 50 to plus 45 ºС;

- pressure from 80 to 110 kPa (from 0.8 to 1.1 bar);

- climatic execution U, placement category 2, 3 GOST 15150.

The conditional designation of the unit in order, correspondence and in another documentation is adopted in accordance with TS TS 010/2011, 012/2011 and ST PC00218035-001-2011 executions and category of accommodation according to GOST 15150.

Example of the designation:

A X-E100 -65-200 -to- 55 -U3 EX II GB C/B IIBT4 x -50 ºС ≤ +45 ºС ST PC00218035-001-2011, where:

- Ah -chemical console horizontal on the support rack;

- E -designation of executive and fire hazardous production;

- 100 -input diameter in mm;

- 65 -exit diameter in mm;

- 200 -nominal conditional diameter of the working wheel in mm;

- K -the symbol of the material of the flow of the pump;

- 55 -type of shaft seal (double end seal-type 153/153 or analogue);

- U -climatic execution;

- 3 -Placement category during operation.

- EX -a special explosion safety sign;

- II -Equipment group;

- GB -the level of explosion protection;

- C/B -type of explosion protection.

- IIB -a group and subgroup of equipment in accordance with the category of explosion hazard of the mixture for which the equipment is intended. Equipment marked as IIB is also suitable, also for use where the equipment of the subgroup IIA is required.

- T4 -the classification of equipment depending on the temperature class of the explosive gas mixture and indicates the maximum surface temperature ºС at which the unit can be operated. Equipment marked as T4 is also suitable, also for use where the temperature class T3, T2, and T1. equipment is required.

- x -designation of additional information on the installation, use and maintenance of equipment. Since the actual maximum surface temperature does not depend directly on the equipment, but mainly on operating conditions (such as heated (hot) fluid pumped by the pump).

- -50 ºС ≤ +45 ºС -the ambient temperature at which the unit can be operated.

When installing a wiped working wheel in the pump, which provides operation on the middle and lower Q-H field curves, in the aggregate brand, after indicating the nominal conditional diameter of the working wheel, the letter “ and " (1st turn) or " b " (2nd turn).

For example:

A Hu100-65 -200 A-K-SD-U3 ST PC00218035-001-2011, where:

O -for hot and crystallizing liquids;

A -the first turn of the working wheel;

SD -double salon seal ( 5 -a single end seal, 55 -double end seal);