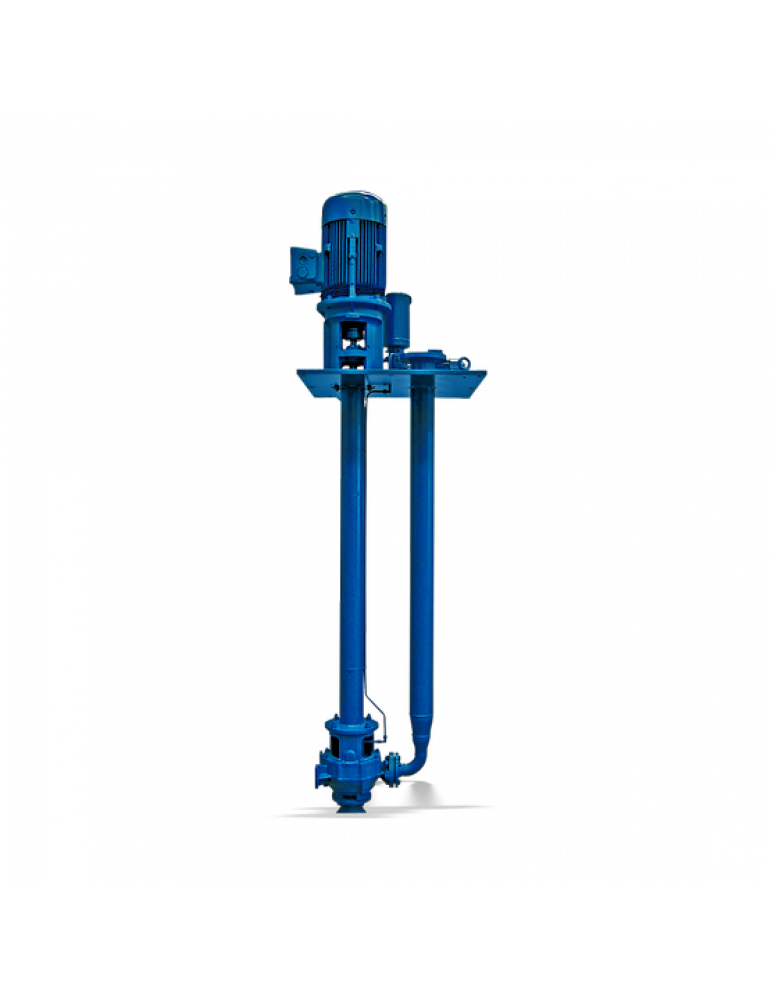

Description < /span>

Processor with a free-hungry wheel, half-open or two-/three-channel wheel. The tightness of the shaft is ensured by a end or an omenus seal with various pipelines in the API. With bearings lubricated oil grease. ATEX performance

Scope

at oil refineries, in chemical and the petrochemical industry, in steel factories, for installations for the removal of scale, in the mining industry, sewer farm.

Review of technical data

q (50hz)

2.0-800, 0 (m³/h)

h (50hz)

0.9-60, 0 (m)

type of bearing

Linging bearing and sliding undergrowth < /span>

separation of the case

transverse (radial)

drive

Elector < /span>

the frequency of the drive engine

50 Hz /60 Hz < /span>

type of drive

Elector < /span>

voltage of the drive engine

Low voltage

electric connector

230/400 V, 3 ~

explosion protection

ATEX (94/9/ EC)

max. Destation depth

5785.0 (mm)

work wheel material (according to the standard E

CA6NM, CF8M, JL1040 < /span>

type of coupling

directly < /span>

type of lubricant

consistent lubrication/lubricant of the pumped environment

max. Permissible fluid temperature

100.0 (° C) /span>

installation of the unit

"Dry" installations, flooded.

shaft material (according to the standard EN)

Aisi-316l, F- 114

characteristics on absorption

Nonamovy. /span>

Tear stove

Yes < /span>

type of case

Spiral Corps

type of working wheel

Open, free-free working wheel, free Three -channel working wheel

body material (according to the standard EN)

CF8M, JL1040

installation position

Vertical < /span>

type of shaft seal

Salnic stuffing, the shaft sealing ring , end seal

the main areas of application

Industry and technological processes, waste water, oil/gas

max. Working pressure on the pressure sides

16.0 (BAR)

max. Driving power

300.0 (KW)

type of installation

Stationary < /span>

max. rotation frequency

3500.0 (1/min)

& nbsp;

| q (50hz) | 2.0-800, 0 (m³/h) |

| h (50hz) | 0.9-60, 0 (m) |

| type of bearing | Linging bearing and sliding undergrowth < /span> |

| separation of the case | transverse (radial) |

| drive | Elector < /span> |

| the frequency of the drive engine | 50 Hz /60 Hz < /span> |

| type of drive | Elector < /span> |

| voltage of the drive engine | Low voltage |

| electric connector | 230/400 V, 3 ~ |

| explosion protection | ATEX (94/9/ EC) |

| max. Destation depth | 5785.0 (mm) |

| work wheel material (according to the standard E | CA6NM, CF8M, JL1040 < /span> |

| type of coupling | directly < /span> |

| type of lubricant | consistent lubrication/lubricant of the pumped environment |

| max. Permissible fluid temperature | 100.0 (° C) /span> |

| installation of the unit | "Dry" installations, flooded. |

| shaft material (according to the standard EN) | Aisi-316l, F- 114 |

| characteristics on absorption | Nonamovy. /span> |

| Tear stove | Yes < /span> |

| type of case | Spiral Corps |

| type of working wheel | Open, free-free working wheel, free Three -channel working wheel |

| body material (according to the standard EN) | CF8M, JL1040 |

| installation position | Vertical < /span> |

| type of shaft seal | Salnic stuffing, the shaft sealing ring , end seal |

| the main areas of application | Industry and technological processes, waste water, oil/gas |

| max. Working pressure on the pressure sides | 16.0 (BAR) |

| max. Driving power | 300.0 (KW) |

| type of installation | Stationary < /span> |

| max. rotation frequency | 3500.0 (1/min) |