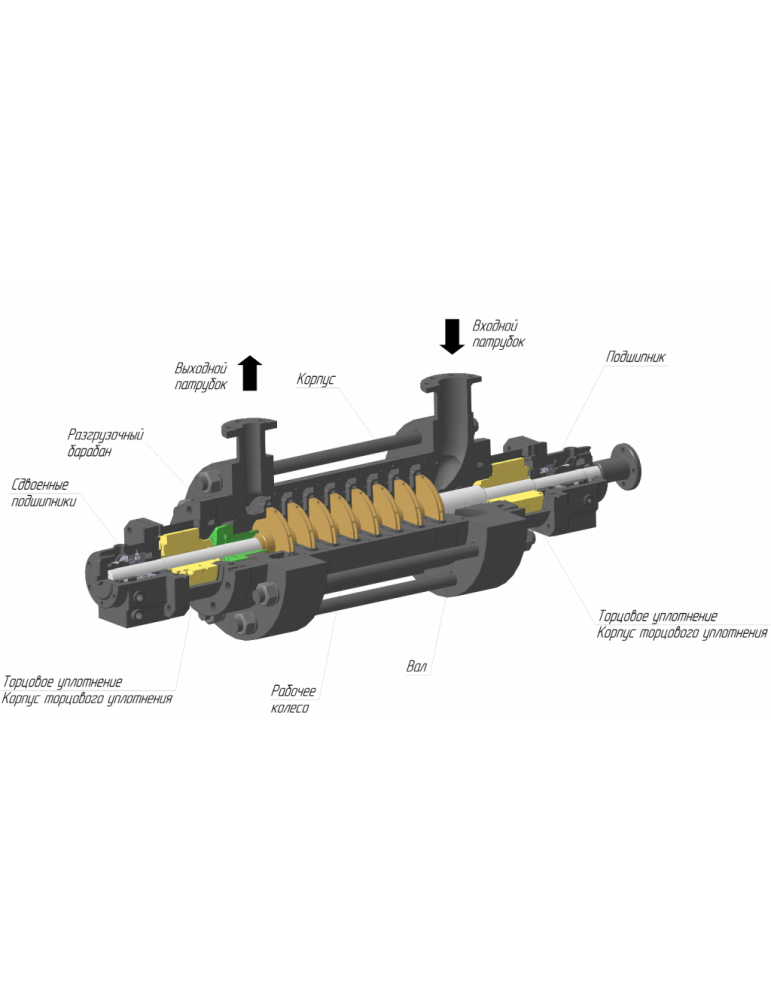

The pump is a sectional structure with a one-sided location of the workplaces. The sectional case consists of a set of sections with a connector in the planes, perpendicular axes of the pump. The sections between themselves and the lids are centered on cylindrical grooves, joints can be compacted either due to metal contacts of sealing belts, or with the help of sealing rings. The guides in the pump are pressed in the section. The sections and lids are interconnected by screed hairpins and form the pump body. Bearing brackets are attached to the lids of the body with hairpins. Together with lids, nozzles and supporting paws are cast. The axial force is balanced by the unloading drum, the water from it is diverted into the ring chamber to the first stage. The end seals are mechanical seals of the Tandem type. The residual axial load is perceived by stubborn roller bearings. Carter bearing lubricant.

The dignity Smaller metal consumption and complexity, unlike a double -hub pump.

The pump is designed in accordance with the API610 and fully complies with safety and reliability requirements.

Used to pump products with a temperature of up to 150̊s. />

The design of the pump is determined by three main factors: temperature, pressure and nature of the pumped liquid.

The absorption and pressure nozzles are calculated taking into account the permissible loads on the API610.

/b>

- A simple design with a minimum number of parts to minimize the size and cost of maintenance;

- increased absorption of the first stage;

- Unloading from axial effort using a fasting drum;

- The implementation of the bearing unit without the need to disassemble the entire pump.

-

No. Electric pump brand Feed, q Ples, n (max, min), m ∆H, Rotation frequency, rpm. Engine power, NED., KW Mass aggregate, kg Dimensional dimensions, p/n (min, max), m, add. LHBHH, mm m 3 /h 1 NDMO 80-40-180/4 29 (17-32) 136 2 2960 22 1500 2000x650x730 2 NDMO 80-40-180/5 29 (17-32) 170 2 2960 22 1650 2000x650x730 3 NDMO 80-40-180/6 29 (17-32) 204 2 2960 30 1750 2240x650x730 4 NDMO 80-40-180/7 29 (17-32) 238 2 2960 37 1870 2240x650x730 5 NDMO 80-40-180/8 29 (17-32) 272 2 2960 37 1920 2240x650x730 6 NDMO 80-40-180/9 29 (17-32) 306 2 2960 45 2000 2500x720x730 7 NDMO 80-40-180/10 29 (17-32) 340 2 2960 45 2120 2500x720x730 8 NDMO 80-40-180/11 29 (17-32) 374 2 2960 55 2260 2800x780x730 9 NDMO 80-40-180/12 29 (17-32) 408 2 2960 55 2610 2800x780x730 10 NDMO 80-40-180/13 29 (17-32) 442 2 2960 75 3030 2800x780x730 11 NDMO 80-40-180/14 29 (17-32) 476 2 2960 75 3380 2800x780x730 12 NDMO 80-40-180/15 29 (17-32) 510 2 2960 75 3730 2800x780x730 13 NDMO 100-50-215/3 54 (32-59) 156 2 2950 37 1650 2240x720x790 14 NDMO 100-50-215/4 54 (32-59) 208 2 2950 55 2080 2240x720x790 15 NDMO 100-50-215/5 54 (32-59) 260 2 2950 75 2680 2500x720x790 16 NDMO 100-50-215/6 54 (32-59) 312 2 2950 75 3030 2800x780x790 17 NDMO 100-50-215/7 54 (32-59) 364 2 2950 90 3410 2800x780x790 18 NDMO 100-50-215/8 54 (32-59) 416 2 2950 110 3970 2800x780x790 19 NDMO 100-50-215/9 54 (32-59) 468