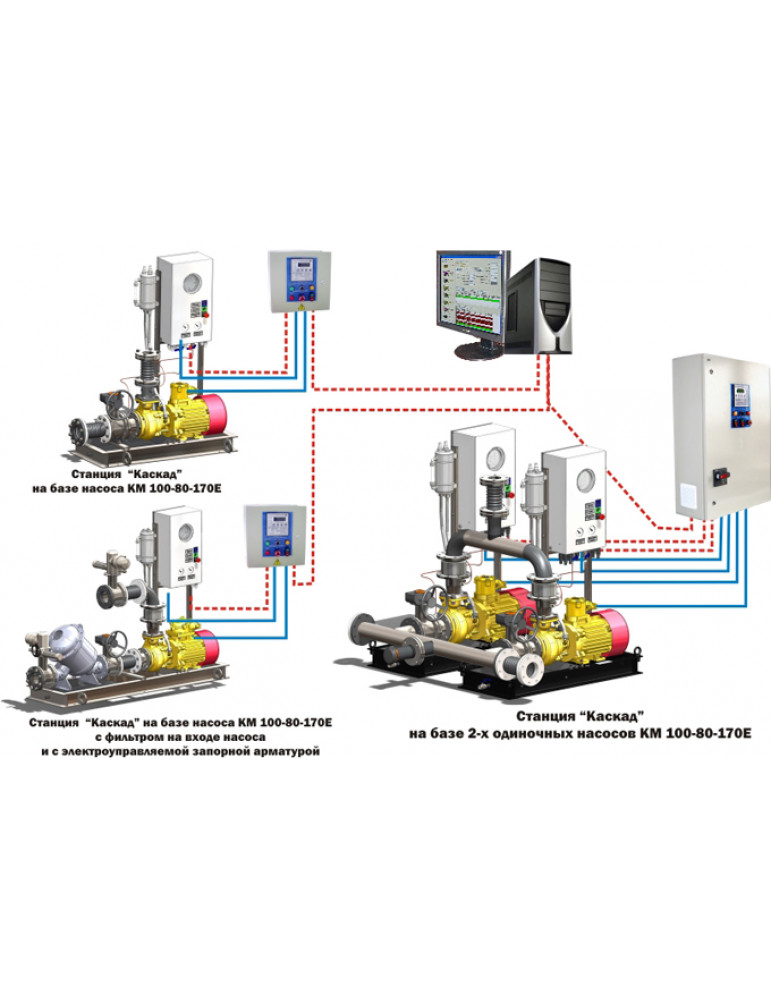

Poosa Station "Cascade " with an automated control system based on units of electric pumps type K, electric pumps of km, KMS of its own production, designed for pumping oil products, temperature from -40 to +50 OS, viscosity up to 10-4 m22/ C (100cst) with the content of solid suspended particles in an amount of not more than 0.2% and a size of not more than 0.2 mm.

The pumping "Cascade" safety requirements GOST12.2.2.003-83, GOST 12.1.019-79, GOST R 52743-2007, "Industrial Safety Rules and oil products PB 09-560-03". "The general rules of explosion safety for explosive and fire hazardous chemical, petrochemical and oil refineries", "Rules for the installation of electrical installations of PUE Gl. 7.3".

The pumping "Cascade" station provides:

- The most safe pumping of oil products;

- Diagnosis of the operation of the pump unit and installed sensors;

- Full protection of the electric motor of the pump unit;

- Management and diagnostics from a computer at a distance of RS485 (Modbus RTU Protocol);

- Intuitively understandable multi -level menu in Russian (all parameters are programmed by buttons on the cabinet controller) or from a computer in communication RS485;

- Textual information on the housing and indigict of the controller controller of the control cabinet on the state of the station, possible malfunctions;

- Manual mode of operation - buttons "Start", "Stop" from the control cabinet or from the pump unit;

- Remote mode of operation - according to the external signal (dry contact) or by communication RS485;

- Work on external sensors (dry contact) - Summary sensor, lower -level sensor, top -level sensor, maximum level sensor, “Accident” input;

- The minimum number of cables (power supply cable is 4 veins, power supply cable 5 cores, RS485 3 cable cable 3 veins, control cable 5 cores);

- The work of the pump unit with any complexes of the ASN, UNM, the KUP in communication RS485, through the operator’s Army program (Modbus RTU protocol from the transfer speed of 9600 - 57600).

The station is made in climatic design, the placement category 2 GOST 15150-69 and is intended for operation in explosive and fire hazardous areas of premises and outdoors of classes 1 or 2 according to GOST R 51330.9-99, in which explosive mixtures of combustible gases or vapors with air related to the air can be formed to categories IIA and IIB and explosive groups T1, T2, T3 and T4 according to GOST R 51330.5-99.

for a separate order, the station "Cascade" is made on any type of pumps K, KM, KMS, D, CG, etc. with relevant permits, as well as the execution of HL in a heated block-box.

| Submission |

Pack, M 3 /h | /h

Ples, m | EL/DV power, kW |

nominal current, and |

mass, kg (no less) |

|

Sucked medium - oil products with a temperature - 40 ...+ 50 ° C, viscosity up to 100 SCT With the content of solid inclusions in an amount of not more than 0.2% and a size of not more than 0.2 mm: |

|||||

| Km 65-50-160-m | 25 | 32 | 5.5 | 10.93 | 300 |

| Km 65-50-160-a-m | 25 | 26 | 5.5 | 10.93 | 300 |

| Km 65-50-160-b-m | 25 | 20 | 5.5 | 10.93 | 300 |

| Km 80-65-140-m | 45 | 15 | 3 | 6.1 | 300 |

| Km 80-65-160-m | 50 | 32 | 7.5 | 14.4 | 300 |

| Km 80-65-160-a-m | 50 | 26 | 7.5 | 14.4 | 300 |

| Km 80-65-160-b-m | 50 | 20 | 7.5 | 14.4 | 300 |

| Km 80-50-200-m | 50 | 50 | 15 | 28.8 | 300 |

| Km 80-50-200-a-m | 50 | 40 | 11 | 21.1 | 300 |

| Km 100-80-170-m | 100 | 25 | 11 | 21.1 | 350 |

| Km 100-80-160-m | 100 | 32 | 15 | 28.8 | 350 |

| To 150-100-200-m | 200 | 40 | 37 | 68 | 600 |

| To 150-100-200-m | 150 | 50 | 30 | 59.5 | 550 |

| To 150-100-200-a-m | 150 | 40 | 30 | 59.5 | 650 |

| To 200-150-250-M | 320 | 50 | 75 | 132 | 900 |

| KMS 100-80-180e | 65 | 35 | 15 | 28.8 | 350 |

| KMS 100-80-180-A | 40 | 35 | 11 | 21.1 | 350 |

| Sucked environment -clean liquids without mechanical inclusions: water, gasoline, kerosene, diesel fuel, alcohol and other neutral liquids, with a viscosity of not more than 2 · 10-5 m2/s, temperature from -40 ° C and density not more than 1000 kg/m 3 . | .|||||

| ASVN-80A-E | 38 | 26 | 11 | 22.5 | 350 |

| Sucked environment - oil products (oil, oil, fuel oil, omty oil) without mechanical impurities | |||||

| W 80-2.5-37.5/2.5 | 37.5 | 25 | 11 | 21.1 | 400 |

|

Working environment: air, non -toxic gases and pairs insoluble in the working fluid. Work fluid: water and other liquids close to water in their characteristics. Designed to create a vacuum in closed devices |

|||||

| VVN 1-12 | 12.2 | - | 30 | 60 | 1500 |