Description < /span>

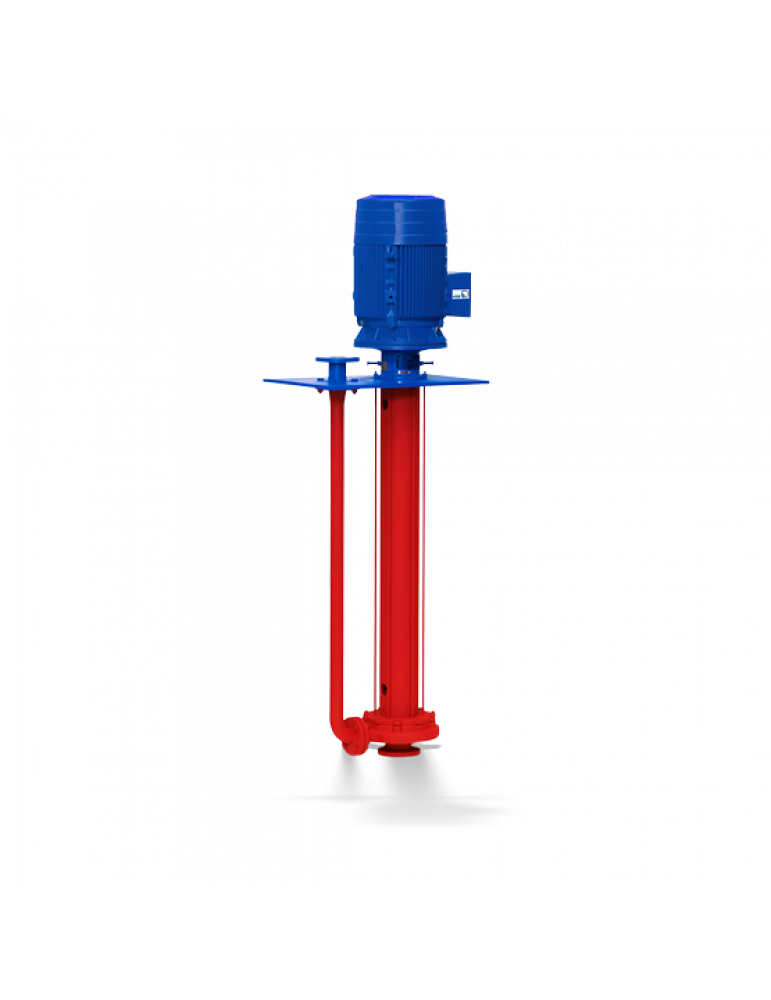

a single-stage pump with a spiral case for vertical installation in a closed tank under the atmospheric pressure, the performance corresponds to EN 733. The immersion depth 2 m.

Scope

for pumping phosphate solutions, supply Lubrication and oil shutter for turbines, generators, large compressors and gearboxes.

Review of technical data

q (50hz)

3.0-740, 0 (m³/h)

h (50hz)

1.5-100, 100, 100, 100, 100, 100, 100, 100, 100 0 (m)

type of bearing

Encouraging

separation of the case

transverse (radial)

the frequency of the drive engine

50 Hz /60 Hz < /span>

type of drive

Elector < /span>

voltage of the drive engine

Low voltage

the number of inputs of the working wheel

Single-flow < /span>

max. Destation depth

2000.0 (mm)

work wheel material (according to the standard E

1.4408 / A743 GR CF8 M , EN-GJL-250/A 48 CL 35b

type of coupling

directly < /span>

type of lubricant

consistent lubricant

max. Permissible fluid temperature

95.0 (° C) /span>

Pack of the pipe

Variant < /span>

maximal working pressure

Pn 10 < /span>

installation of the unit

"Wet" installations

shaft material (according to the standard EN)

1.4462, C45+N < /span>

standard

en 733

characteristics on absorption

Nonamovy. /span>

Tear stove

Yes < /span>

type of case

Spiral Corps

type of working wheel

Radial, closed

type of accession

Fill < /span>

body material (according to the standard EN)

1.4408 / A743GR CF8 M, EN-GJL-250/A 48 CL 35b

eclass

36410101, 03641000, 36410100 < /span>

installation position

Vertical < /span>

type of shaft seal

Highlights of the shaft

the main areas of application

Industry and technological processes, waste water

body material

Gray Cast iron, stainless steel < /span>

max. Working pressure on the pressure sides

10.0 (Bar)

max. Driving power

90.0 (KW)

type of installation

Stationary < /span>

max. rotation frequency

3500.0 (1/min)

| q (50hz) | 3.0-740, 0 (m³/h) |

| h (50hz) | 1.5-100, 100, 100, 100, 100, 100, 100, 100, 100 0 (m) |

| type of bearing | Encouraging |

| separation of the case | transverse (radial) |

| the frequency of the drive engine | 50 Hz /60 Hz < /span> |

| type of drive | Elector < /span> |

| voltage of the drive engine | Low voltage |

| the number of inputs of the working wheel | Single-flow < /span> |

| max. Destation depth | 2000.0 (mm) |

| work wheel material (according to the standard E | 1.4408 / A743 GR CF8 M , EN-GJL-250/A 48 CL 35b |

| type of coupling | directly < /span> |

| type of lubricant | consistent lubricant |

| max. Permissible fluid temperature | 95.0 (° C) /span> |

| Pack of the pipe | Variant < /span> |

| maximal working pressure | Pn 10 < /span> |

| installation of the unit | "Wet" installations |

| shaft material (according to the standard EN) | 1.4462, C45+N < /span> |

| standard | en 733 |

| characteristics on absorption | Nonamovy. /span> |

| Tear stove | Yes < /span> |

| type of case | Spiral Corps |

| type of working wheel | Radial, closed |

| type of accession | Fill < /span> |

| body material (according to the standard EN) | 1.4408 / A743GR CF8 M, EN-GJL-250/A 48 CL 35b |

| eclass | 36410101, 03641000, 36410100 < /span> |

| installation position | Vertical < /span> |

| type of shaft seal | Highlights of the shaft |

| the main areas of application | Industry and technological processes, waste water |

| body material | Gray Cast iron, stainless steel < /span> |

| max. Working pressure on the pressure sides | 10.0 (Bar) |

| max. Driving power | 90.0 (KW) |

| type of installation | Stationary < /span> |

| max. rotation frequency | 3500.0 (1/min) |