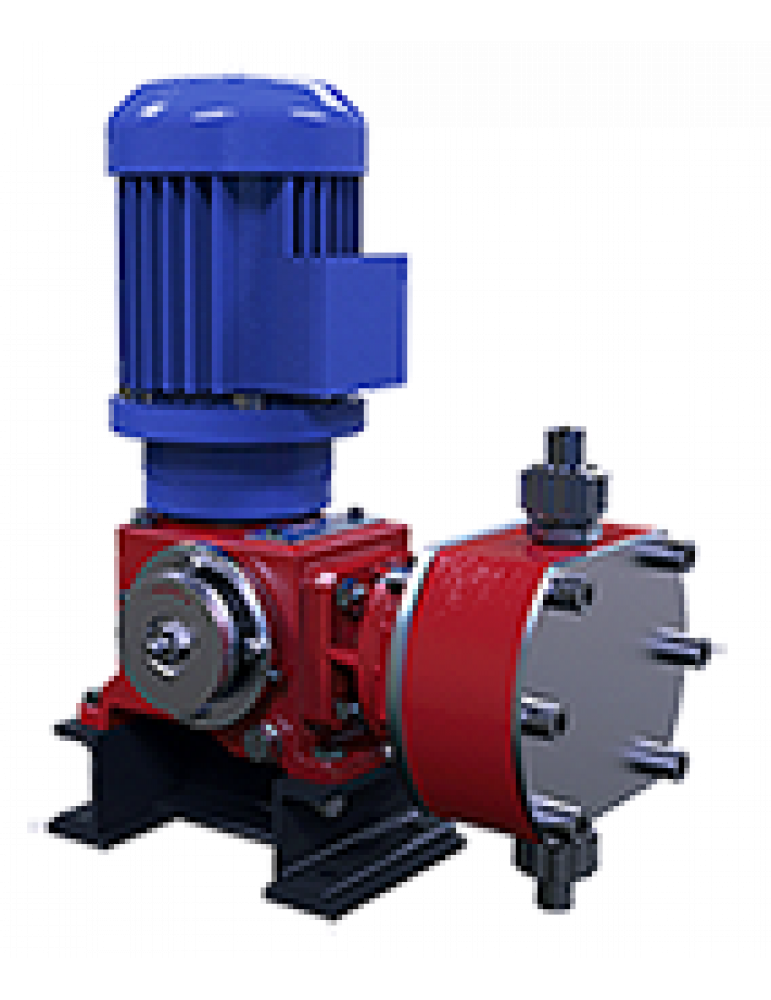

Membrane pumps of a new type-NDM membranes 1 (with mechanical loading of the membrane).

Working range of pumps of this type from 30 to 1250 l/h; Permit pressure 16 kgf/cm 2 , the flowing part can be made of metal and plastic (PP, PVC, PVDF, F-4).

Dosage membrane membranes of NATM types of NATM correspond to TU 3632-003-46919837-2007.

membrane dosage pumps are intended for work In chemicalization of technological processes at objects:

- Vodokanals, water treatment and cleaning of sewage Water;

- oil and gas industry

- chemical industry, petrochemistry, production polymers;

- Energy.

The scope of hermetic pumps is determined by the resistance the materials of the running part in the metered environment and the execution of electrical equipment included in the package. Features of the design of the membrane dosage pump provide the absence of leaks of pumped liquids into the external environment.

"> ">"> ">"> ">"> ">"> ">"> ">"> ">"> ">"> ">"> "

"> ">"> ">"> ">"> ">"> ">"> ">"> ">"> ">"> ">"> "

The main advantages of membrane dosing NATM pumps 1

A feature of NDM pumps is simplicity Designs that allows you to reduce the cost of a membrane unit, preserving all its advantages:

- Complete tightness, which allows them to use them to pave them to pave them to pave them. aggressive environments (toxic, explosive) , expensive liquids (essences, aromatic substances, etc.) and media, which need protection against atmospheric exposure;

-

for increased reliability Performing with multi-layer membranes made of fluorine KhTZ stamps (coldly hardened).

- The opportunity The possibility of remote control and regulation consumption of the pump unit, which makes it possible to use this equipment for operation in the introduction of “low-coded technologies”, in harsh natural-climatic conditions.

- low price in its class.

"> ">"> ">"> ">"> ">"> ">"> ">"> ">"> ">"> ">"> " The main parameters and characteristics of the membrane dosage NDM1 pump

nominal feed, l/h, l/h, l/h.

The drive (engine) of the membrane drive (engine) NDM1 pump, kW 0.25 0.37 0.55 1.1 1.5 The maximum stroke length, mm. 6 < /span> 10 < /span> 16 < /span> 16 < /span> maximum pressure, kgf/cm 2 120/ 8 < /span> 100/50*(30 **) 10 < /span> 16 < /span> 400/500 10 < /span> 630/800 10 < /span> 1250/ 6 < /span> 1000/1250 10 < /span>