Pumps and units Centrifugal artesian are designed for pumping, as well as pumping out of buried water, oil, oil products and other fluids that are inappropriate for ferrous metals and rubber. With the content of mechanical impurities no more than 0.1% (by mass).

characteristics of the pumped environment:

-

The temperature of the pumped water is up to 308 K (35 ° C),

oil and oil products - from 233 to 353 K (from minus 40 to plus 80 ° C). - The maximum density of oil and oil products is 0.95x103 kg/m³

- Kinematic viscosity from 0.01x10 - 4 to 0.8x10 - 4 m²/s.

Artesian oil units are made in explosion -proof design and allow pumping liquids in explosive or fire hazardous industries and installations.

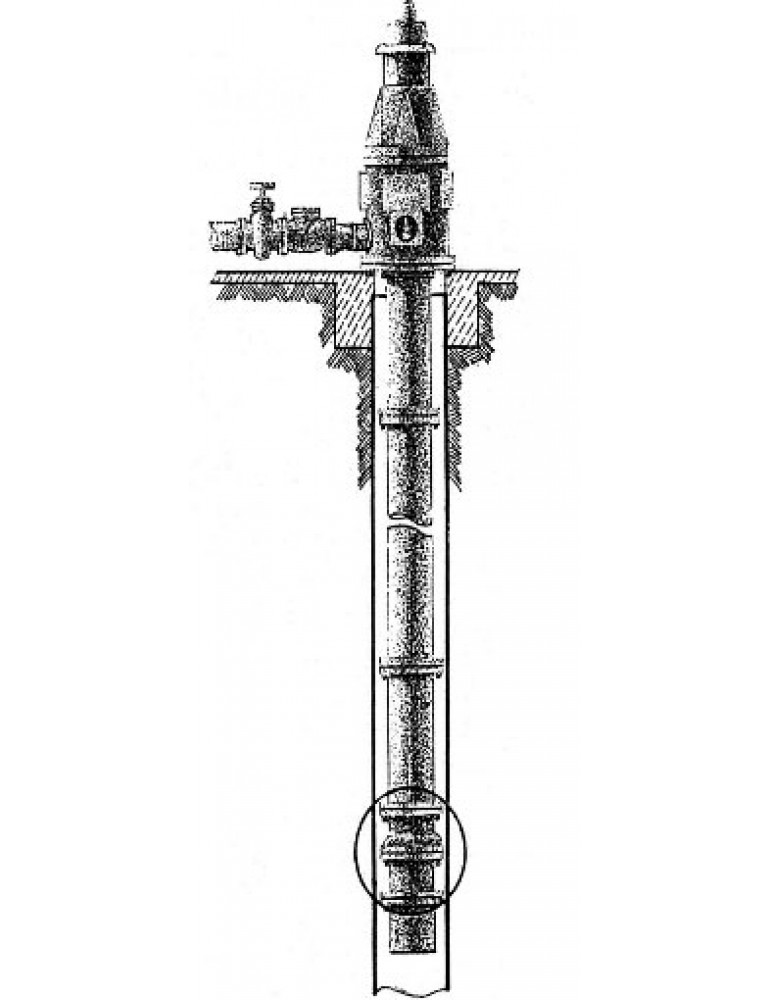

A feature of artesian pumps is that the pumping part is lowered into the tank, and the electric motor is located at the top on the surface. Their combination is carried out by a set of sections with a transmission shaft located in them, which allows pumping liquids from tanks buried to 80 meters. The minimum distance to the bottom of the tank is not less than 200mm.

| The size of the unit | Feed, m³/h | Ples, m | Rotation frequency, rpm | Power, kW | Max. Submissive sections | Dimensional exchanges, mm | Mass, kg |

|---|---|---|---|---|---|---|---|

| A20A-18x1 | 600 | 28 | 1470 | 75; 380 | 9 | 27000x1040x1040 | 5765 |

| A20A-18X1-M1 | 600 | 28 | 1470 | 75; 380 | 9 | 26825x1040x1040 | 5580 |

| A20A-18x3 | 600 | 85 | 1470 | 250; 380 or 250; 6000 | 33 | 83310x1040x1040 | 15395 |

| A24A-18X1 | 1200 | 45 | 1470 | 16 | 43640x1040x1040 | 11460 | |

| A20na-22x3* | 600 | 65 | 1470 | 160; 380/660 | 8 | 11875x1040x1040 | 3715 |

| A20na-22x3-m1* | 600 | 65 | 1470 | 160; 380/660 | 8 | 13560x1040x1040 | 3840 |