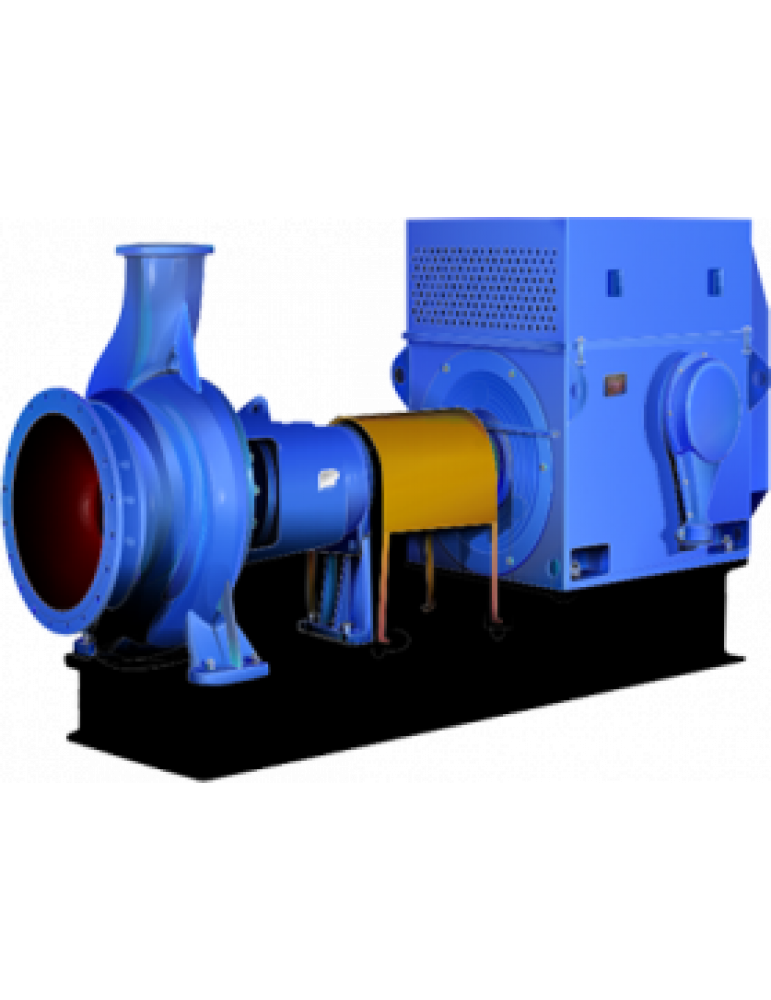

Pumps-centrifugal console single horizontal location of the shaft and axial fluid supply. Designed for pumping wood-fiber masses with a concentration of up to 8%, hydrogen pH from 2 to 13%, temperature up to 373k (100 ° C) in technological processes of pulp and paper production.

Design

- The pressure pipe is displayed on the pump axis And directed up. The form of the allotment is spiral.

- Working Wheel of Pumps of Closed or Open Type with chipping blades.

- The shaft seal is a soft seal.

- The Pulse Drive-from the electric motor through Bushing-fracture clutch.

- Material of the Pange Part-Corrosionno-Corrosionno -strible steel.

Sucked Wednesday

Papers and wood-fiber semi-finals up to 8%, hydrogen indicator (pH) from 2 to 13, a temperature of up to 100 ° C. The flow of the pumps is made of stainless steel, resistant in sour and alkaline media.

Technical characteristics

| Mark | feed, m³/h | Pess, m | Rotation frequency, rpm | engine power, kW | |||||||

| bm 40/16 | 40 < /span> | 16 < /span> | 1500 < /span> | 5.5 < /span> | |||||||

| bm 56/31.5 < /td> | 56 < /span> | 31.5 < /span> | 1500 < /span> | 11 < /span> | |||||||

| bm 67/22.4 < /td> | 67 < /span> | 22.4 < /span> | 1500 < /span> | 11 < /span> | |||||||

| bm 80/15 | 80 < /span> | 15 < /span> | 1000 < /span> | 7.5 < /span> | |||||||

| bm 118/31.5 < /td> | 118 < /span> | 31.5 < /span> | 1500 < /span> | 22 < /span> | |||||||

| bm 125/20 | 125 < /span> | 20 < /span> | 1000 < /span> | 18.5 < /span> | |||||||

| bm 190/45 | 190 < /span> | 45 < /span> | 1500 < /span> | 55 < /span> | |||||||

| bm 236/28 | 236 < /span> | 28 < /span> | 1000 < /span> | 37 < /span> | |||||||

| bm 315/15 | 315 < /span> | 15 < /span> | 1000 < /span> | 30 < /span> | |||||||

| bm 355/63 | 355 < /span> | 63 < /span> | 1500 < /span> | 110 < /span> | |||||||

| bm 475/31.5 < /td> | 475 < /span> | 31.5 < /span> | 1500 < /span> | 75 < /span> | |||||||

| bm 530/22.4 < /td> | 530 < /span> | 22.4 < /span> | 1000 < /span> | 75 < /span> | |||||||

| bm 800/50 | 800 < /span> | 50 < /span> | 1500 < /span> | 200 < /span> | |||||||

| bm 900/12.5 < /td> | 900 < /span> | 12.5 < /span> | 750 < /span> | 55 < /span> | |||||||

| bm 900/31.5 < /td> | 900 < /span> | 31.5 < /span> |

| ||||||||