The deep pump is designed for the operation of wells complicated by sand and the influence of oil associated gas and allows oil to produce oil - 5.10 - 4m2/s (500C), containing up to 3% of the mechanicism and not more than 100 m 3 /m << SUP> 3 gas factor.

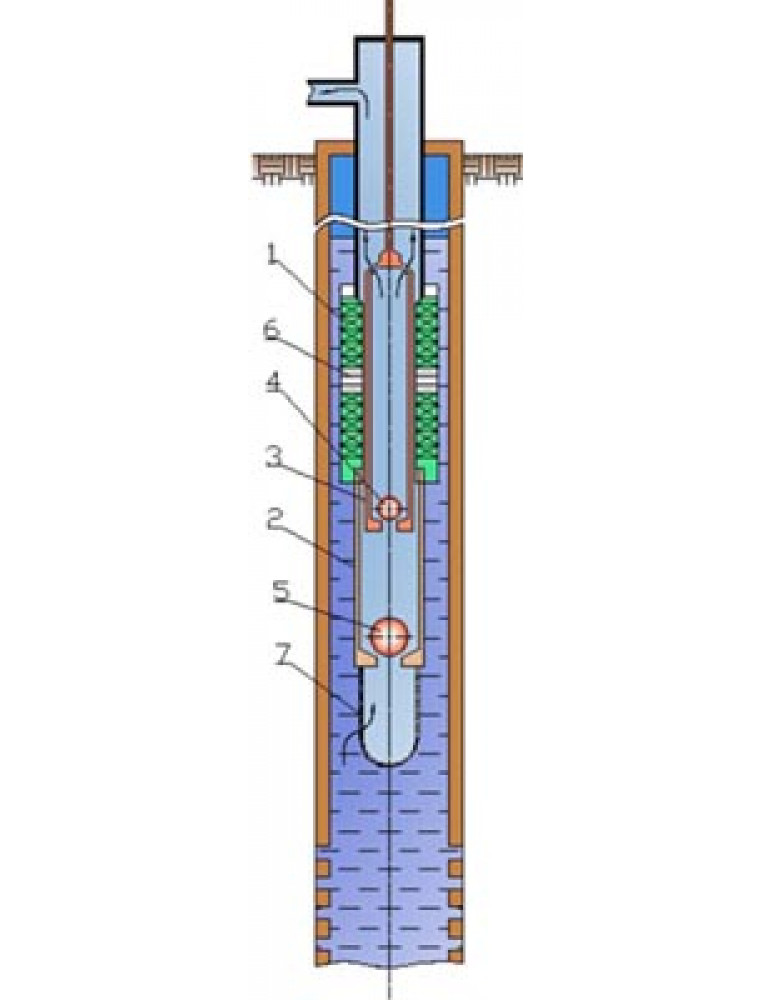

The pump can operate at high temperatures - up to 150 ° C. The pump consists of a short cylinder made in the form of a sealing device, an elongated plunger (3) with a discharge valve (4), a receiving valve knot with an enlarged passing cross section (5), rigidly fixed on the executive pipe (2). In the cylinder, two packages (1) are scored from elastic elements, separated by a dividing chamber with holes (6) for draining oil during underground repair. At the reception of the pump, a gas -pebble anchor is mounted (7). The new constructive execution of the pump cylinder and the receiving valve made it possible to significantly reduce the volume of the harmful space in the pump - up to 10 times.

Pumps with a diameter of the plunger 32, 38, 47, 57, 70 and 86 mm are designed for forced selection of plastic fluid in a wide range of viscous characteristics and sand content, provide environmentally friendly well repair, without rosily oil.

| ">; Characteristics of pumped liquids | |

|---|---|

| Flooding | up to 99% |

| Temperature | up to 393K (120 ° C) |

| Mechanical impurities | up to 5 g/l |

| Dynamic viscosity | Up to 5 PAS (5000 SPZ) |

| Mineralization of water | up to 60 g/l |

| Free gas | 10% in volume |

| Hydrogen sulfide | up to 50 mg/l |

| pH = 3-8 | |