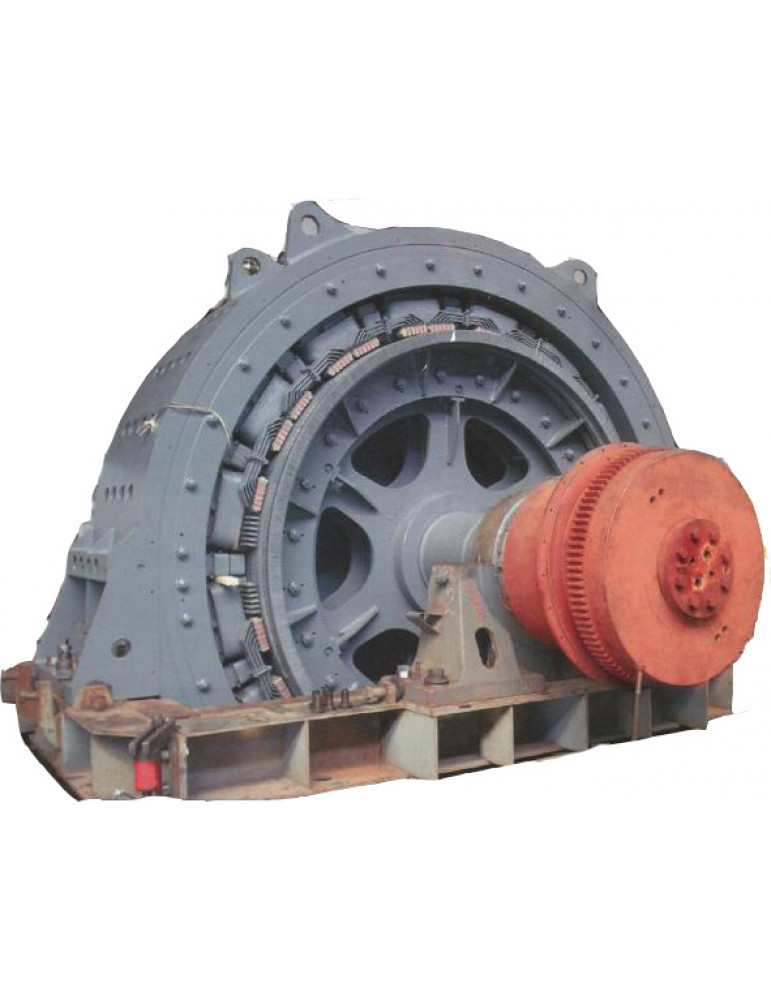

DC motors of the P2 18 - 25 dimensions series

The engine of the P2-630-204.5-4 K series

Designed for the drive of the B cast manipulator lines.

Ventilation - forced, in a closed cycle with air coolers.

The warranty life of the engine is set three years from the date of commissioning, however, no more than four years from the date of proceeding it through the state border of Ukraine.

Nominal power - 800 kW

Nominal voltage - 750 V

Nominal current - 1240 A

Rotation frequency - 40 rpm

Efficiency - 84%

The dynamic moment of inertia of the anchor is 5150 kgm2

Mass - 46000 kg

The engine can be used for a lower rated voltage with a corresponding decrease in power and rotation frequency.

The engine excitation is independent, voltage 220 or 110 V

The number of reverses per hour is no more than 1000

Permissible current overloads:

- working, at a nominal frequency - 3.0 I nom, where I is noma - the nominal value of the current is not often repeated at the speed of rotation close to zero

- rotation lasting no more than 15 s

- lasting not more than 10 s - 3.2 I nom

- disconnecting - 3.5 I nom

Medium -ry (during the technological cycle) current, no more than the engine of engine

Sustainable engine operation at a rotation frequency close to zero is provided by the control circuit.

Heating class for all windings - “f”

Isolation is designed for voltage, in:

- Wraps of anchor chain from the case - 1500

- excitation windings - 1000

Trinching engines P2 21-25 dimensions

DC electric motors of the P2 21 - 25 dimensions are designed for severe operating conditions as the main and auxiliary drives of rolling mills and other mechanisms

The electric motors are performed in a closed design with forced ventilation of the fan through a closed or open cycle using air coolers. Cooling air should be clean without the content of oil vapors, acids and conductive dust in concentrations not exceeding 0.2 mg/m3.

The direction of rotation is reversible. Reverses are carried out by a change in the direction of the current in the anchor circuit.

The insulation from the hull of the anchor circuit and excitement windings is designed for the operating voltage of 1000 V. The insulation class of windings is “f”.

Electric motors are designed to work in a temperate climate, in the operating conditions of UHL4. Height above sea level - 1000 m. Electric motors must withstand a long load on the current of 1.15 INO. And within two hours - 1.25 INO. If the temperature of the windings is not higher than the permissible for isolation of class “f”

The structure of the conditional designated

P2 -HXX-XXX-XXXX:

P2 - designation of a number of engines;

XXX - the height of the rotation axis (630, 800, 1000mm);

Xx - an armature diameter number - 21, 22, 23, 24, 25 (anchor diameter in mm is performed, respectively, 2150, 2500, 2850, 3100, 3400);

X - the length of the length of the anchor core (3, 5, 6, 7, 8);

X - the number of brushes on each marriage (8, 14);

C - performance of sliding bearings;

X - climatic execution (UHL, O, T);

X - Placement category (4, 3).

For the execution of UZ, the minimum ambient temperature is minus 100s.

The engines are raised closed, with forced ventilation through a closed or open cycle using air coolers.

Permissible working overloads lasting no more than 15C:

- at a nominal speed of rotation - 2.25 I nom.;

- at the maximum rotation frequency - 1.8 I nom.;

Disabled overloads:

- at a nominal speed of rotation - 2.75 I nom.;

- at the maximum rotation frequency - 2.0 I nom., Where I nom. - nominal value of the current.

When working with these overloads, engines allow the maximum rate of current change in the anchor chip up to 100 I nom/s.

Moderate engines operating in a temperate climate withstand the load on a current of 1.15 and noma for a long time during overheating, allowed for isolation of class “f”.

Nominal voltage at the anchor - 930v.

The rated voltage of independent excitation of engines is 220V. For the possibility of switching to a voltage of 110V in the engines, the four ends of the excitation winding

Engine power is carried out from static or rotating voltage converters.

The insulation of class “F” based on polyamides. The insulation of the windings of the anchor circuit relative to the engines housing is designed for a voltage of 1500V, the excitation winding is 1000V.

The engine reverse is carried out by a change in the direction of the current in the anchor circuit.

Engines allow a three -time force forcing excitation.

The warranty service life of engines for rolling mills of 24 months from the date of start -up, however, no more than 36 months from the date of proceeding across the state border of Ukraine.